#ITMA 2019

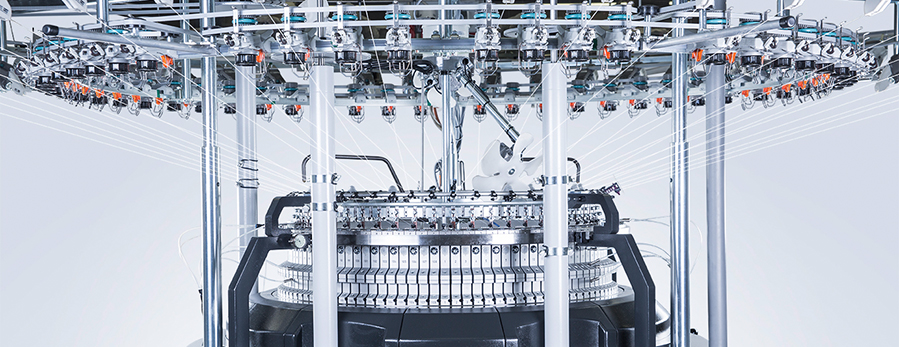

Mayer & Cie.’s new MJ 3.2 E makes a tailor-made job of body mapping

A mesh and body mapping specialist

“Body mapping is the supreme discipline for an electronic single jersey jacquard machine, the 100- metres sprint, as it were,” says Marcus Mayer, Mayer & Cie. managing director in charge of technical development at the German circular knitting machine manufacturer. “In developing our MJ 3.2 E we had that same challenging task in mind and are certain that the MJ 3.2 E will be a strong contender and a powerful track ‘athlete’.”

Body mapping, like a similar structure, mesh, is much in demand in the sporting market segment. Athleisure is currently a key growth driver for circular knits.

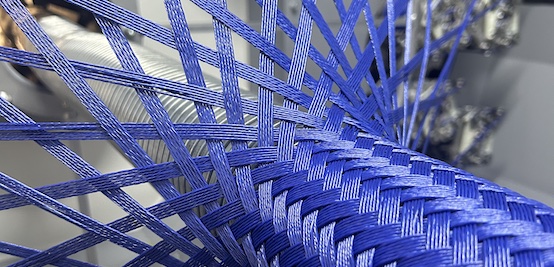

Mesh is a net-like hole pattern. A finer basic thread, usually a monofilament yarn, is responsible for the hole structure while the thicker plating thread – cotton for example – provides the requisite thick spots. Mesh structures require one-sided plating and the basic thread is invisible in the finished fabric. Mesh can serve as both a fashion and a functional element, such as by ensuring ventilation of selected body areas.

Body mapping too takes the different perspiration areas of the human body into account, but double-sided plating creates the patterns. Body mapping also requires larger plain-coloured areas in the back or abdominal region. Because different colours are used, inaccuracies in the plating would be visible. Furthermore, body mapping structures almost without exception require elastomeric plating. That is the only way to achieve a body-hugging fit that also ensures a high degree of freedom of movement.

The new MJ 3.2 E takes all these challenges into account. Reliable plating of both the basic and the plating thread is key. For both the machine can process elastomer yarn. Explaining the benefit, Marcus Mayer says that “if the basic thread is elastomer plated the knitwear is highly elastic. If the plating thread is used, the overall elastomer content of the fabric is lower and a more open structure is possible”. New cam parts and improved thread guides ensure reliable plating. The machine’s conventional sinker technology provides flexibility. This means both press off and plating are handled optimally with a wide variety of yarns and the MJ 3.2 E will always yield a high fabric quality.

One machine, three focal points

The MJ 3.2 E’s capabilities extend way beyond its body mapping and mesh specialities. That is due to the machine’s 3-in-1 concept (there are two conversion kits for the MJ 3.2 E). To produce mesh and body mapping structures the machine runs on 2-way technology and 3.2 feeders per inch. It also runs on 2-way technology to achieve peak productivity for full jacquard, reaching a speed factor of up to 850. That corresponds to an up to 20 per cent higher output than that of the two established

Mayer & Cie. electronic jacquard machines, the Relanit 1.6 E and the Relanit 2.4 E. Customers who focus on maximum flexibility and pattern variety can rely on the MJ 3.2 E with 1.6 feeders and 3-way technology.

Summarising, Marcus Mayer says “the MJ 3.2 E is an important addition to our machine portfolio for two reasons. For one, it produces high-quality elastomer-plated body mapping structures; for another, it enables our customers to work more productively than with our previous single jersey electronic jacquard machines.”

Mayer & Cie. machine portfolio for sporting usesAlong with the new MJ 3.2 E and the two Relanit machines Mayer & Cie. has other machines in its portfolio that are peak sportswear performers. The MV4-3.2 II and the S4-3.2 produce fine-gauge knitwear made of various synthetic fibres. Both knit fine gauges, the MV4-3.2 II even up to E60, and are suitable for making running shirts, for example.

The D4 2.2 II and the D4 3.2 II, both of them double jersey machines, are also popular models for the production of sportswear. Both produce right/right structures, fine touch and different 8-lock structures. “Overall, double jersey is currently less in demand for sportswear, but its microstructures are truly impressive,” says Mayer & Cie. trend scout Hardy Bu?hler, adding that “the trend away from smooth surfaces is plain to see. Every user is looking for something special such as an attractive pattern. That is why honeycomb effects, double face and pique? structures are highly sought-after.”