#ITMA 2019

PICANOL presents a brand new airjet machine at ITMA 2019 Barcelona

In total, Picanol will have 12 machines on display at ITMA Barcelona. In addition to 5 new airjet weaving machines, Picanol will also present 5 rapier weaving machines with many new developments. Furthermore, a rapier machine in Jacquard execution will be on display at the Bonas booth and a terry airjet at the Stäubli booth. The Picanol booth will be located in Hall 4, Booth 101.

In an ever-changing world, the needs of the weaving mills as well as the expectations of the operators are evolving rapidly. The increasing awareness regarding environmental topics, increasing costs and the availability of resources and skills, as well as the digital revolution, will push us in new directions.

For this reason, Picanol products are designed with a focus on four principles:

1) Smart Performance: Performance is the first requirement for any weaving machine or feature, and the most obvious indicator is the theoretical maximum speed. Very often, however, the gap between this theoretical speed and the effective speed under real life circumstances is huge. That’s why we at Picanol conceive our machines around the principle of ‘Smart Performance’: an intelligent machine design combined with self-learning software, allowing the best possible practical speed and real performance under any given circumstances.

2) Sustainability Inside: When it comes to waste prevention and energy consumption reduction, Picanol has been taking up its responsibility for years. Our machines are conceived with a built-in capacity for sustainability. We have proven this with our pioneering Sumo Drive concept, introduced in 1996, and up until today still the most energy efficient main drive available. Sustainability is also about waste management. We not only reduce waste but try to avoid it completely. Our EcoFill feature serves here as an excellent example.

3) Driven by Data: Everybody realizes that in the next decades digitization will become ever more important. Data have to be captured, made accessible and usable for production optimization and artificial intelligence. Since the first introduction of electronics on weaving machines in the 70s, Picanol has been at the forefront of digitization. With every new machine, we continue to be a trendsetter in this field and to further deploy Industry 4.0 in the weaving industry: the self-setting machine is just around the corner.

4) Intuitive Control: Our children inspire us, especially in their intuitive and effortless handling of technology. Wireless-ready, robust and designed for maximum instant readability, the new generations will not accept anything less than that. This user centric design is also integrated in the concept of our machines, making all operations and interventions intuitive, easy and self-explanatory.

As a proof of our commitment to these four principles, we will present our latest developments in rapier and airjet technology. When it comes to rapier technology, Picanol once again sets the benchmark in various aspects. We will deliver the proof, on a denim application, that a machine can be performant, versatile, sustainable, digital and user-friendly at the same time!

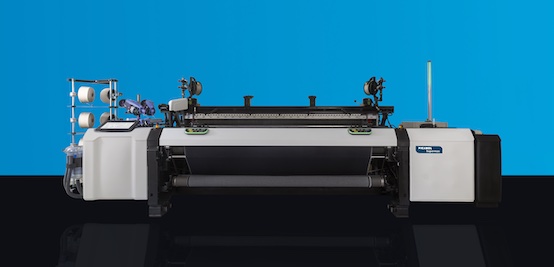

Our brand new airjet machine, the OmniPlus-i, is however the première we reserved for ITMA 2019 Barcelona. OmniPlus-i is definitely the benchmark in airjet weaving. This further builds on the solid base of nearly 40 years of experience in airjet weaving, during which over 100,000 airjet machines have so far been shipped. OmniPlus-i is combining this extensive airjet expertise with a clear vision of the future! OmniPlus-i is featuring a redesigned reed motion, optimized relay nozzle set up and can be combined with SmartShed, the full electronic controlled shedding motion.

In total, Picanol will have 12 machines on display at ITMA Barcelona: 5 airjet machines and 5 rapier machines at the Picanol booth. Furthermore, a rapier machine in Jacquard execution will be on display at the Bonas booth and a terry airjet at the Stäubli booth.

Below our detailed overview of the machines and highlighted features:

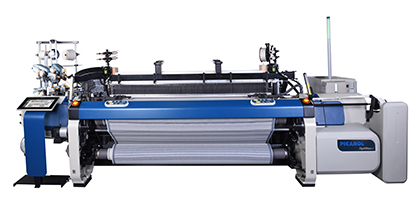

OmniPlus-i-4-D-190 weaving a Car Seat fabric

A machine loaded with all the features that set the benchmark for our new principles. Smart Performance, Sustainability Inside, Driven by Data and Intuitive Control. OmniPlus-i, our new benchmark.

Highlighted features:

New Display and signal lamps

Blue11 EasySet Prewinders

Digital shedding motion (SmartShed)

Waste cord free RHS (CordLess)

PosiJet main nozzle

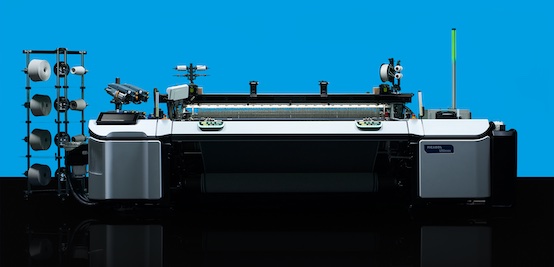

OmniPlus-i-4-R-190 weaving a parachute fabric

Weaving light filament fabrics without having to choose between speed and flexibility. Reaching the required high fabric quality standards becomes even easier with the increased inbuilt stability of the insertion system.

Highlighted features:

New Display and signal lamps

Blue11 EasySet Prewinders

Air consumption monitoring and management system (AirMaster)

Automatic Relay Valve Drive (ARVD II Plus)

Pick Repair Automation (PRA II Plus)

OmniPlus-i-4-P-280 weaving Sheeting

A clear example of a high end sheeting style. Thanks to the unique air tucking in maximum width flexibility is guaranteed. With the new OmniPlus-i the practical running speeds are lifted to an even higher level.

Highlighted features:

New Display and signal lamps

Blue22 EasySet Prewinders

Air consumption monitoring and management system (AirMaster)

Air Tucking In device for continuous reed

OmniPlus-i-4-D-190 weaving Poplin

A proof that even light fabric segment can benefit from the OmniPlus-i platform. Digitization, maximum flexibility and still running the highest speed.

Highlighted features:

New Display and signal lamps

Blue22 EasySet Prewinders

Digital shedding motion (SmartShed)

Air consumption monitoring and management system (AirMaster)

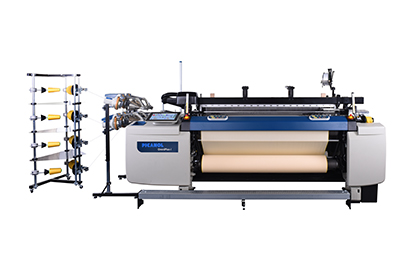

OmniPlus-i-4-P-190 weaving Bottom Weight

The proven standard for weaving of bottom weight. Specified with the focus of reaching the highest possible production speed in this fabric segment. A clear demonstration of the potential of the new OmniPlus-i.

Highlighted features:

New Display and signal lamps

Blue22 EasySet Prewinders

Air consumption monitoring and management system (AirMaster)

Waste cord free RHS (Cordless)

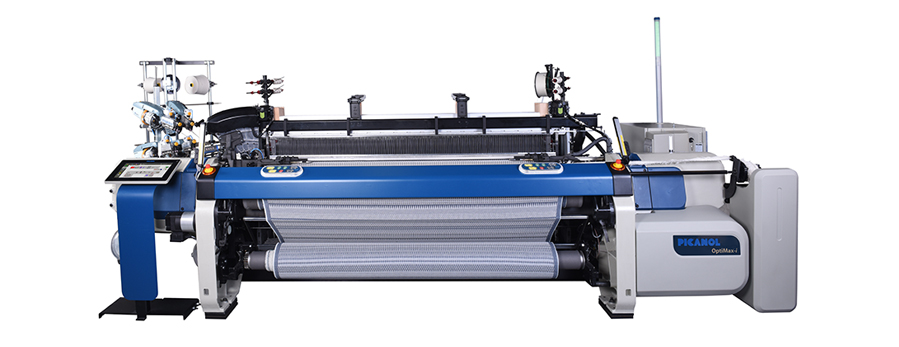

OptiMax-i-4-R-220 weaving Denim

The digital loom! A machine driven by data, relying on smart performance, always with sustainability in mind.

Highlighted features:

New Display and signal lamps

Guided GC gripper

Electronic Right Gripper opener (ERGO)

Quick Style Change (QSC)

Waste reduction system LHS (EcoFil 4Colours)

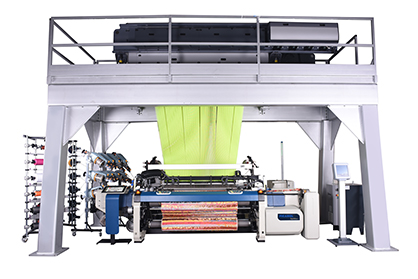

OptiMax-i-4-R-460 weaving a coating fabric

A new milestone in weaving coating fabrics, Free Flight gripper-system extended until 460 cm at highest insertion rates. No Guide-hooks required anymore on widths above T360!

Highlighted features:

New Display and signal lamps

Pneumatically controlled backrest (DWC)

Laserstop warp stop motion

Electronic Righthand side Gripper Opener (ERGO)

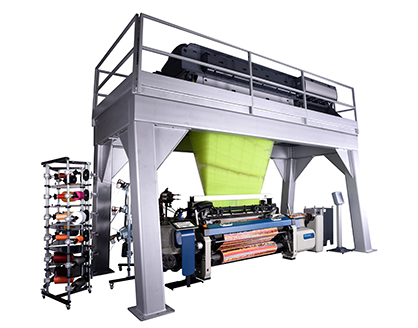

OptiMax-i-4-P-540 weaving Ground Backing

Our answer to weavers looking for versatile machines to weave a wide range of Technical Fabrics. Thanks to Guided Positive Grippers, Agro-textiles in a range from ground covers to open anti-hail nets become possible.

Highlighted features:

New Display and signal lamps

Guided Positive Gripper GPG

Waste reduction system LHS (EcoFil 4Colours)

Pneumatically controlled backrest (DWC)

Mechanical Tucking in for tape filling

Waste ribbon winder

OptiMax-i-12-J-190 weaving upholstery

The ultimate versatility! No longer a dream, but reality thanks to our revolutionary positive gripper system. Smart performance throughout the complete insertion process.

Highlighted features:

New Display and signal lamps

Flexible Positive Gripper (FPG)

Electronic Filling Tension Control (EFT)

Electronically controlled weft cutter SmartCut

TerryMax-i-8-J-260 weaving Terry

The benchmark for terry weaving. No limitations in design, aiming at maximum performance in combination with ultimate quality.

Highlighted features:

New Display and signal lamps

Versatile guided gripper (GCv)

Electronic Right Gripper Opener (ERGO)

Electronically controlled filling brake PosiFlex

Directly driven pile control system

Electronically controlled pneumatic pile tensioner

At the Stäubli booth: TERRYplus Summum 8-J-260

The benchmark for terry weaving at the highest possible performance, benefiting from all the strong points of Picanol’s extensive Airjet experience.

Directly driven pile control system

New 8-color main nozzle

Pick Repair Automation (PRA II plus)

Air consumption monitoring and management system (AirMaster)

Pile height monitoring

Needle roll control

At the Bonas booth: OptiMax-i 8-J-190 weaving Decoration fabric.

Versatility as the new normal. Allows weaving the widest range of yarns in warp and weft thinkable with a negative rapier, combined with maximal digitization.

Free Flight with raceboard (VB)

Electronically controlled weft cutter (SmartCut)

Electronic Righthand side Gripper Opener (ERGO)

Motor driven jacquard