#ITMA 2019

Monforts introduces the CYD multi-colour yarn dyeing system at ITMA 2019

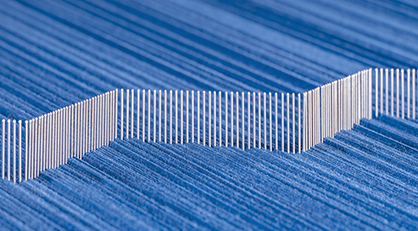

This latest CYD denim processing technology integrates new functions and processes into the weaving preparatory processes – spinning, direct beaming, warping and assembly beaming, followed by sizing and dyeing – in order to increase quality, ?exibility, economic viability and productivity.

“Denim finishing is a field in which Monforts has an undisputed lead and we have been working closely with our many partners in the key denim manufacturing countries of China, Bangladesh, India, Pakistan, Mexico and Brazil to develop new advanced solutions,” says Monforts Head of Denim Hans Gerhard Wroblowski. “The CYD system has been developed in response to a very strong market demand.”

Econtrol® is a pad-dry process employed in Monforts continuous dyeing in which the reactive dyestuff is fixed to the cellulose fibres during drying and the CYD multi-colour yarn dyeing system introduces a number of new concepts based on it, including the unique Eco Bleach process.

This is the first bleaching system for yarn treatment available on the market and will be of particular interest to denim manufacturers.

The Eco Bleach system is combined with the washing units and the fabric is then dyed immediately, resulting in considerable savings in waste water and chemicals.

The most effective dyeing process for fabrics is now being applied for yarn dyeing and it is possible to process short batches of between 5-10,000 metres of yarn in order to produce 2-300 metres of fabrics in a single continuous process.

In its raw state, cotton has a light brownish/yellow tinge and bleaching is necessary to ensure its pure whiteness prior to dyeing. On conventional systems, this involves a separate process step, but with the CYD multi-colour yarn dyeing system it is now integrated into the Econtrol® process for full dyeing pre-treatment.

Visit Monforts at stand D101 in Hall 2 during ITMA 2019 to learn more.