#ITMA 2019

The THEN Smarflow – setting a new standard in jet dyeing

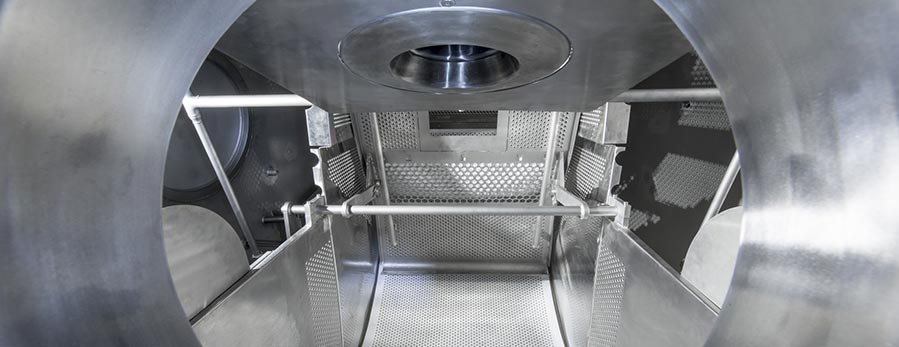

The THEN Smartflow TSF is designed to achieve the lowest possible energy and water consumption rates available on the market for jet dyeing, with achievable liquor ratios for a full load up to 300kg with a reduced kier volume and a liquor ratio down to 1:3.5 for cotton and 1:2.5 for synthetics.

FONG’s Europe has a number of patents pending on the innovative new features of this machine, including the Smartflow’s fabric transport design. This is based on a smart, winchless fabric transport system which eliminates the need for a loading rope, and a circular plaiter with programmable rotation speeds which provides full filling of the drop zone.

The chambers can accommodate variable loads in terms of both weight and material type down to 40kg for extremely flexible processing, and each Smartflow TSF unit can be equipped with up to 8 chambers, in order to fully maximise productivity, while taking up to 40% less floor space than competing systems.

“The newly-developed nozzles and reel-less transport in combination with smart controlled circular plaiting and variable chamber adjustment provide even fabric treatment without entanglements and the highest loading capacity with the lowest kier volume,” explains FONG’s Europe Sales and Marketing Manager Richard Fander.

Another innovation is the new bath preparation unit (BPU) and its patented satellite tank.

“As the process times of jet machines have been continuously optimised over the past few decades, they have required an increasing number of service tanks for dyes, auxiliaries and hot water, adding both expense and additional space requirements,” says Mr Fander. “Our new BPU and satellite tank, with its automatic dosing and mixing programmes, working in combination with the THEN temperature management system, ensures the recipes are supplied in exact quantities, with dyes and auxiliaries well diluted and heated to the required temperature extremely rapidly.”

“The new THEN Smartflow allows fully reproducible processing with the optimised use of raw materials, water and energy, for perfect dyeing every time,” he concludes. “Hydraulically driving the fabric without the use of a transport winch opens the door to reducing the tension during treatment and results in the highest relaxation of stretch and spandex fabrics.”

FONG’s Europe will be at stand D101 in Hall 2 at ITMA 2019 with Then and Goller, and Xorella will be at stand D203 in Hall 6.

Earlier, Fong’s Europe will also be at the Techtextil show in Frankfurt, Germany, from May 14-17th, at stand F01 in Hall 3.0.