#ITMA 2015

ITMA 2015: New Products presented by SANTEX RIMAR GROUP

Textile finishing

SANTASYNPACT is the latest addition to the Santex family of knits finishing machines. The main goal is to provide the highest performance and best fabric quality with minimum production costs. SANTASYNPACT is a combination of rubber belt shrinkage and felt belt compacting. With this new development compaction results are significantly improved. For example production speed is up to 60 m/min, which is 2 to 3 times higher than conventional felt compacting systems. At ITMA latest version is presented with special designed felt belt features to ensure the sensitive treatment of cotton or cotton blended knits. Sperotto Rimar is presenting the new DECOFAST 3.5, the best performing decatising machine on the market with new features that further increase the performance of the world reknown Decofast. DECOFAST 3.5 redefines the decatising process, applying it to other fibers, with new controls and innovative solutions to get better results and increase hand and performance for wool, viscose and knitted fabrics. PlaNa allows to process natural fibers and have long lasting anti-shrinkage and dyeing permeability without chemicals. It is the first industrial scale solution limiting the usage of natural resources to produce easy-care and eco-friendly natural fibers.

Technical textile

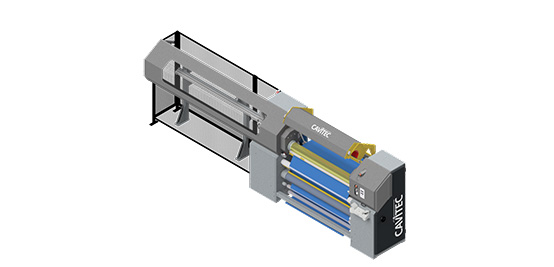

Cavitec is showing the new CAVIMELT P+P. It is a streamlined machine developed with the goals of precision, production and cost effectiveness in Hotmelt Coating and Laminating using the rotogravure system.

This compact design integrates the unwinder and rewinder in one machine frame. Operating speed is up to 40 m/min and allows coating weights from 3 – 80 gsm. The machine is delivered pre-wired, assembled and tested. The CAVIMELT P+P stands for Plug+Play, built for clients who want short installation and commissioning time. Isotex is announcing its new partnership with Covestro, former BAYER Material Science. The partnership has been signed to develop technologies for water based synthetic leather, evolving into a project for the development of new technologies and joint market activities.

Greentech

The newly acquired SOLWA is focused on Green Technology. Solwa is an innovative Company in the water treatment sector (human and agricultural needs) and dehydration processes, using only renewable technologies. The last eco-friendly solution is DryWa the most innovative green system to dry sewage sludge in wastewater treatment plants, reducing drastically volumes, costs and industrial waste. Applications range from civil (towns and villages water treatment plants) to industrial (food processing and such).

SANTEX RIMAR GROUP welcomes visitors at ITMA MILANO 2015 | HALL 10 BOOTH D101