#Dyeing, Drying, Finishing

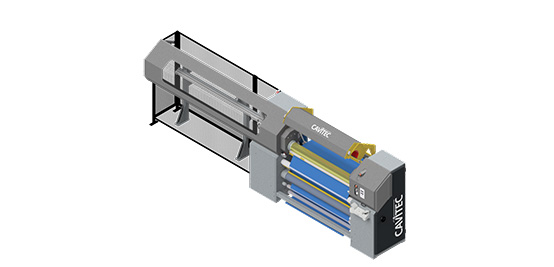

The new Cavimelt Pro embodies bi-functional coating with quick and easy switching

The machine customers have been waiting for…

The task is easy to describe: two layers are bonded together to create a laminate. Yet the process itself draws on pure science underpinned by detailed knowledge of materials, adhesives, technology and machines. That’s how to achieve the best results for demanding customers manufacturing the end-product.

Cavitec a brand of Santex Rimar Group is the world leader in coating, laminating and impregnating dedicated to identifying and meeting the critical requirements of companies in this sector: “We have engaged in countless discussions with customers and potential customers over several years, combining the insights gained with our own experience to design exactly the machines that customers want,” says Stephane Fernandez, Head of Sales and Lab (Hotmelt Division) at Cavitec. Cavimelt Pro is the new bi-functional hotmelt laminating machine which enables switching between rotogravure and full-surface coating quickly and easily, thanks to new technology.

Quick-change head

Cavimelt Pro offers a carefully thought-through solution, down to the last detail. In the priming position, the dosing roller is open and the tool holding device is pivoted down. This allows the doctor blade holder and the side dams to be changed, to switch the coating. Using side dams for roll coating means this process can be started immediately. The gravure roller is easily exchangeable with a smooth transfer roller.

The quick-change application head combines gravure and full-surface coating in one single system. With this, it is possible to change in a few seconds from one coating method to the other, without the use of tools.

Innovative details are the dosing roller driven by an individual motor for smooth operation and the special positioning of the doctor blade, which avoids the risk of leaking, even with extremely low viscosity values. A big advantage is the high-precision wedge gap control between dosing and gravure/application roll to increase or decrease the coating weight steplessly.

The hot solution

Cavimelt Pro is based on hotmelt technology. Hotmelt adhesives commonly used in textiles are one-component solvent-free thermoplastic polymers (non-reactive) or thermoset pre-polymers (reactive) heated to melting point before application. Hotmelts are applied in a hot plasticized state onto a substrate material such as wovens, knits, nonwovens, foams, membranes, films, nets, silicon paper etc. With this process, substrates are not subject to any deteriorating thermal stress.

In some applications, the material is coated only to change the surface composition, but more often the purpose is to bond or glue two layers of material together to build a composite material.

Cavimelt Pro is the two-in-one solution covering the most important application range, and offering users the opportunity to extend their customer base.

Flexibility, quality and sustainability

Full-surface coating is established in mattress ticking and grinding paper production. Applications for rotogravure cover breathable active wear, protective wear and also lingerie, upholstery and automotive seats and interiors, hygiene and medical products, technical composites and materials for roof underlay etc. Cavimelt Pro was also designed for sensitive materials and innovative applications. It offers flexibility from using membranes of 5 micrometers (one tenth of the diameter of a single human hair) and foam of 20 millimeters of thickness.

The multi-roller coating machine masters each single process perfectly due to precise mechanical control of factors like tension (vital for filmy materials) and even pressure on the full width of the roll. Applying a correctly-defined temperature is essential for reliable adjustments and constant spread on the roll surface.

Empowering users to achieve unmatched coating results and meeting high sustainability standards make Cavimelt Pro ultimately the machine that customers really want. Its hotmelt technology is an environmentally-friendly process, free of solvents and water. Furthermore, as no drying or sintering is necessary Cavimelt Pro also scores in energy-saving aspects. “Cavimelt Pro unites the full set of advantages which can drive success in the finishing business,” says Fernandez.