#ITMA 2015

CREALET introduces solutions for specialized weaving machines at ITMA 2015

CREALET's reliable products and innovative solutions are employed in warp let-off and cloth takeup systems as well as in specialized weaving machine manufacture. With these products, customers worldwide are securing a decisive edge in tough competition: from perfectly tailored “Upgrade Packages” for weaving and warp knitting machines to comprehensive conversions of weaving machines for specific market requirements.

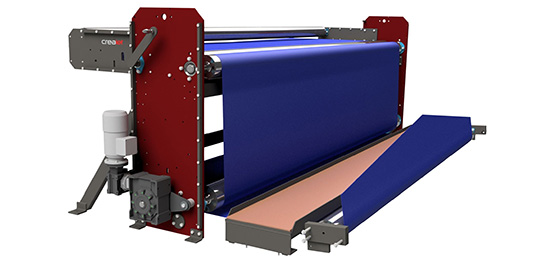

A new business area – specialized weaving machines for wide technical fabrics CREALET is now promoting its new offer in specialized weaving machine manufacture:

CREALET together with IQ-SPS is building specialized weaving machines for wide technical fabrics.

These textiles are used in trade fair construction, stage technology as well as in film and photo studios. Additional applications include woven agro and geo textiles.

In the specialized weaving machine manufacture, CREALET is taking on the electronic warp supply of the warp beams integrated in the weaving machine and is manufacturing additional sub-units for the warp supply from the creel or from additional warp beam stands.

Furthermore, CREALET's sales organization will be made available for global marketing. The first installed machines for these fields of application are operating to the customers' utmost satisfaction. Additional concrete projects are in progress.

- Electronic let-off and cloth take-up devices

- Warp beam device on weaving machines

- Warp beam stands for additional warp beams behind weaving and warp knitting machines

- Warp feeding devices between the creel and weaving machines

- Electronic selvedge yarn spool controls

- Tire cord sub-units consisting of the feeding unit and batch winder

CREALET is looking forward to conveying the new impulses at ITMA Milan