#ITMA 2015

Stäubli at ITMA Milano 2015

At the same booth a new carpet weaving machine developed by Stäubli’s business unit Schönherr carpet systems will demonstrate its capabilities. Exclusive carpet samples will be presented. Customers interested in technical textiles can get an overview of the entire range of Stäubli machines, which enable the production of the most complex fabrics. Additionally, at booth B102 in Hall 7 Stäubli and its business unit DEIMO knitting solutions and drive systems will exhibit state-of-the-art electronic drives and control solutions mainly for knitting machines.

Among the products being exhibited at booth B111/B112 in Hall 1 are:

Jacquard machines Three complete Jacquard installations on weaving machines will be demonstrated: As an impressive premier, visitors can see the production of African damask at high speed on a type SX Jacquard machine equipped with a specific harness with 12,696 cords in conjunction with an air-jet weaving machine operating at a rate of approximately 950 weft insertions per minute. The weaving machine and the Jacquard machine are both operated by individual electronically synchronized drives, which is a special feature of this set-up. The second noteworthy installation features the new LXL Jacquard machine with 11,682 hooks and Stäubli harness. This machine is particularly suitable for large-format applications and will be weaving an OPW airbag (one piece woven airbag) on a 280cm wide reed. The third installation consists of a rapier weaving machine and a LX Jacquard machine with a Stäubli harness producing extraordinary fantasy ladywear with remarkable designs.

At another demonstration stand the new LX12 Jacquard machine for weaving narrow fabrics such as ribbons and labels will be shown with 192 hooks and harness with 8 repeats. Visitors can also see the highly regarded UNIVALETTE Jacquard machine in operation, developed particularly for weaving name selvedge. As usual, the Stäubli booth features two levels. From the upper level, visitors can closely observe the Jacquard machines in operation.

Dobbies and cam motions The third generation of Stäubli’s rotary dobbies, the S3060/3260 series, can be seen with many application examples at the Stäubli stand and the booths of many other weaving machine manufacturers. This new generation of rotary dobbies reaches new heights of performance and reliability.

To complete the presentation of Stäubli shedding systems, a cam motion of the refined positive type 1600 series is also being demonstrated at the booth.

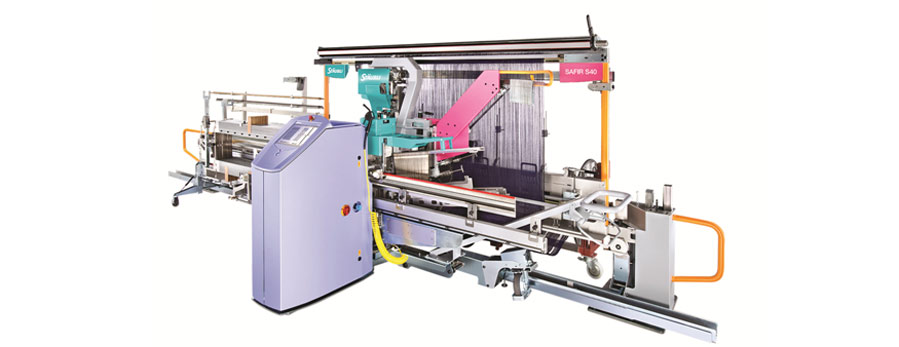

Weaving preparation systems This Stäubli business unit has furnished hundreds of dependable workhorses to weaving mills worldwide and is now launching two additional products at ITMA. The SAFIR S60 is being demonstrated drawing in a four-colour 175cm-wide warp with Nm 135/2 and Nm 170/2 cotton yarns without a lease. The mobile SAFIR S40 drawing-in machine can be observed in a surprising display.

The warp-tying process will be demonstrated with two warp-tying machines: MAGMA for technical and coarser yarn counts and the proven TOPMATIC for standard applications, handling even the finest yarns.

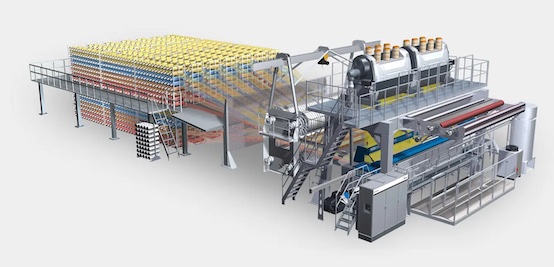

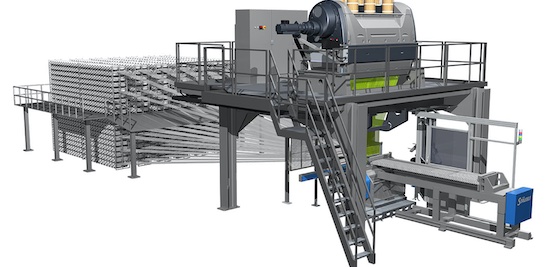

Carpet weaving The Stäubli business unit Schönherr carpet systems boasts another spectacular product launch: Visitors can discover the new ALPHA 500 carpet-weaving machine in operation, weaving different types of carpets. Carpet samples showing off with recently developed effects like the “Traditional carpet effect” or the “Magic Weft Effect 3”, produced on ALPHA 400 and 500 carpet-weaving machines, can also be admired at the booth.

Technical textile weaving Visitors interested in technical textiles will have the perfect opportunity to talk to our experts and discover an interesting display explaining the TF weaving system, launched in spring 2015. TF is a complete weaving system with a maximum of modularity, ideally allowing individual configuration. The TF system, developed and produced by Stäubli, is designed to fulfil specific needs of future-oriented weavers of new fabric types such as heavy multilayers, multilayers with new types of structure and material mix, reinforcing fabrics for lightweight applications and spacer fabrics. Visitors will see astonishing fabric samples.

Separate booth no. B102 in Hall 7 With its business unit Deimo knitting solutions and Deimo drive systems, Stäubli is showing its latest developments on two sock-knitting machines. Also to be seen are a variety of servo motors, electronic control solutions, input/output devices and related programming tools mainly for the textile industry.

Visit the Stäubli booths B111/B112, Hall 1 and B102, Hall 7 All visitors are cordially invited to inspect these product highlights at the Stäubli booths and to discuss their needs and expectations with Stäubli specialists.

….and more Additional examples of Stäubli products can be seen during ITMA Milano at various stands of Stäubli partners in numerous applications with Jacquard machines, dobbies and cam motions.