#ITM 2024

More efficiency and sustainability for warp preparation

Inline energy recycling during drying, BLUEDYE for environmentally friendly indigo dyeing and innovations for less downtime - the KARL MAYER Warp Preparation for ITM 2024

"Turkey is a very important market for us. We want to provide momentum here for our customers who are pressing ahead with their investment projects. We also expect the direct exchange with them to provide us with information about development trends in the current difficult business environment," explains Dieter Gager, Vice President Sales of the Warp Preparation business unit at KARL MAYER.

The focus of the exhibitions for the warp preparation sector is on the topics of cost-effectiveness and sustainability.

Lower costs and environmental impact during sizing and indigo dyeing

The brand new system CASCADE offers customers a solution that enables them to significantly reduce steam consumption on sizing machines and dyeing systems. The basis for this is efficient energy recycling within the cylinder dryer: part of the system's process steam flows is reused to heat up the final cylinder stages, in which the residual moisture is removed from the yarn at lower pressure and temperature values. Depending on the process conditions and system design, a steam saving of around 7% is thus possible and demonstrably so. A machine dashboard provides real-time data on the amount of recycled steam measured by a sensor. The values can be used to calculate the corresponding reduction in CO2 equivalents and costs.

For the denim industry, which is strongly anchored in Turkey, KARL MAYER has a media show for the BLUEDYE in its trade fair baggage. Thanks to clever technological details, the indigo dyeing unit is three times more efficient and two times cleaner than conventional counterparts on the market.

Solutions for maximum machine availability

Other innovations for the warp preparation industry focus on machine availability. Smart Size Box is a technology that monitors the condition of wear components and therefore makes a valuable contribution to predictive maintenance. The customer benefits from significantly less unplanned downtime.

In addition, a combined Care X-Tend and Connectivity Package will be presented based on the Care Solutions offerings for warp knitting. The product for next-generation after-sales service offers, among other things, easy access to fast remote assistance. Unlike conventional teleservice support, images and large volumes of data can now also be exchanged easily and securely, minimizing interruptions to operations. A ticket system is to be introduced in a further expansion stage. This feature, which has already been successfully launched in warp knitting, ensures transparency and efficient management of service requests. Market requirements play a central role in further developments.

"We are looking forward to talking to customers about our Care X-Tend and Connectivity Package at ITM. This exchange is very important for us to ensure that we meet customer needs with our offerings," says Beat Schnurrenberger, Managing Director of KARL MAYER Textilmaschinen AG.

Maximum productivity for warp sampling and sizing

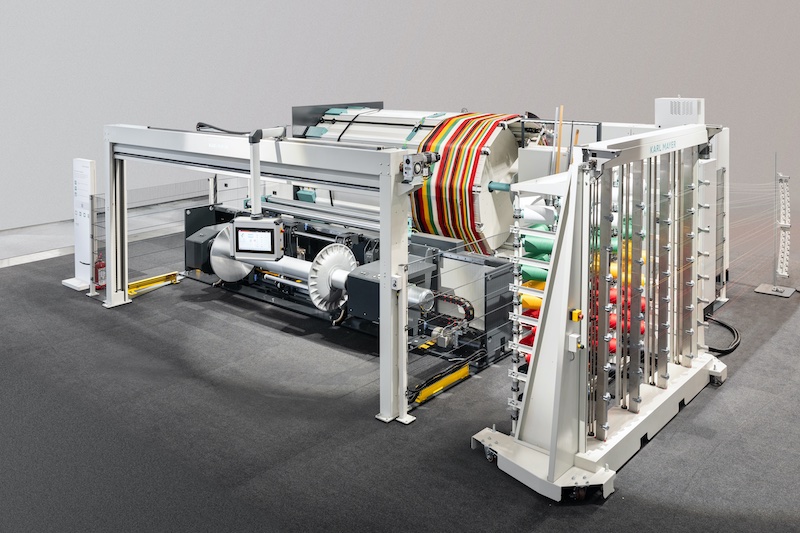

The MULTI-MATIC® 32 Compact and the LINK-MATIC® system, which will be presented with information material, contribute to the topic of maximum efficiency.

The new MULTI-MATIC® 32 Compact warp sampling machine offers twice the productivity of the previous model without taking up more space and enables simple, fast pattern changes. Thanks to the short changeover times, the customer can react flexibly to the needs of the market.

The LINK-MATIC® system is a sophisticated automation solution that also considerably simplifies batch changeovers on indigo and sizing machines, thereby increasing productivity. An output increase of up to 30% is possible, depending on the number of batches. In addition, yarn waste can be reduced to a minimum.