#ITM 2022

Mahlo will present solutions for current challenges at ITM

Measuring and control technology for efficient production

The ITM in Istanbul is the most significant textile technology show in the region, bringing together industry manufacturers and visitors from all over the world. Mahlo participates with its partner Masters Limited, focusing of straightening and process control technologies for the growing Turkish textile market.

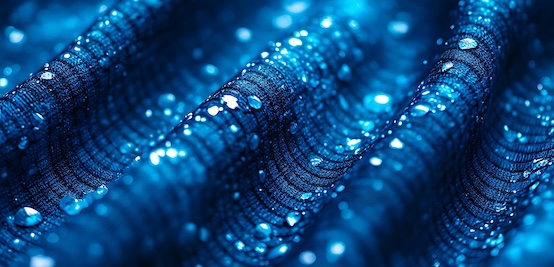

For textile finishers in Turkey and all over the world applies the same: In most applications, distorted fabric is one of the biggest problems to be solved. They must be eliminated in order to preserve the full utilisation value of the product. In addition to that, sustainability and saving of resources in production is becoming more and more important. And at the end of the day, production also has to be profitable for the manufacturer. Not an easy task!

“But Mahlo has the means to support textile producers with these challenges”, Areal Sales Manager Adnan Andac says. The systems of the German machine builder ensure product quality as well as production efficiency: “The weft straightener Orthopac RVMC-15 is the epitome for straight goods.” Based on experience reaching back over 75 years, the machine offers the latest technology for correcting distortions and optimising the processes all around the stenter. Optoelectronic scanning with oscillating lens and DSP (digital signal processor) is probably the most sensitive and versatile system on the market.

Mahlo has variants for every textile structure, from heavy and stiff goods such as carpets and denim to sensitive, flexible textiles. The products range from pure sensors for distortion detection to complex, automatic straightening systems, individually configurable and equipped with process control systems.

Ready for Industry 4.0

The new generation of Mahlo straighteners, sensors and control loops is also ready for Industry 4.0. If a customer uses suitable sensor technology and the appropriate networking, he can access the machine from everywhere, provided he has an Internet connection.

With these standards, the generation 15 Mahlo machines are not only optimally equipped for the future. They also help to save costs and raw materials and improve product quality. This in turn results in satisfied customers and ultimately end consumers