#ITM 2018

SMIT presents brand-new product SMIT GS980

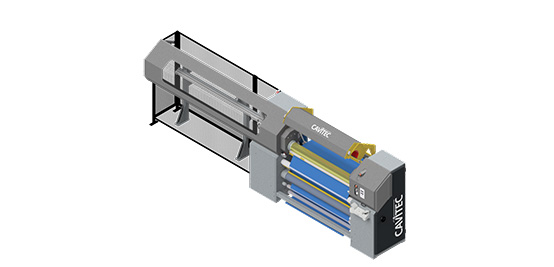

According to SANTEX RIMAR Group the new SMIT GS980 is the fastest free flight rapier machine of the market and has improved in terms of versatility, performance, production quality, efficiency and sustainability.

The free flight ribbons system marks out SMIT weaving machine since years: smart and flexible, SMIT GS980 has been designed and manufactured in Italy combining some of the most reliable SMIT features with groundbreaking function solutions that make SMIT GS980 an asset that will keep its value for a long time.

Fabrics for apparel, home textile, technical applications and exclusive yarns and patterns can today be woven with excellent quality on SMIT GS980.

2018 represents a significant milestone for SMIT which celebrates 80 years after the foundation in 1938.

The machine name has been given after the 80th anniversary of SMIT which was founded in Italy and soon turned out to be an estimated leading manufacturer of weaving machines.

"SMIT GS980 will bring more value to our customers and the best ratio between productivity versus running costs. At our booth we will be weaving denim, curtains and our famous high-quality terry towel fabric" says Simone Rancan, SMIT CEO, who concludes: "The quality of the fabric produced with our machines has always been a reference for the market and with the new SMIT GS980 we will surely continue to exploit this advantage. The general trend of moving towards productions of higher quality fabrics is already happening and some of our customers at the moment are exploiting some market niches where they can find more profitability: in these circumstances our new SMIT GS980 is the right technology for forward momentum".

"Thanks to SANTEX RIMAR GROUP combined know-how we are committed to innovation and machinery improvement, considering the whole complementary processes and specific customers' needs. During the tradeshow it will be possible to see SMIT GS980 for the first time and meet our staff."

Visit SMIT at ITM 2018 In hall 2 at booth 215a and SANTEX RIMAR GROUP in hall 12 at booth 1206.