#Fabrics

Getzner Textil takes fabric quality to the next level

Ten Years of Research for a Better White

White is not just white – a glance at Getzner’s latest collection makes that clear. For nearly a decade, the development team has been working to meet the demands of a high-quality yet competitively priced white fabric. After an intensive project phase last year, the result is a quality that excels both visually and in terms of performance.

The fabric is highly resistant to yellowing, greying, and greenish discoloration – and remains stable even after numerous washes. Another key advancement: the switch to an innovative finishing process that further enhances the fabric’s properties. This not only makes production more efficient but also significantly increases the product’s longevity.

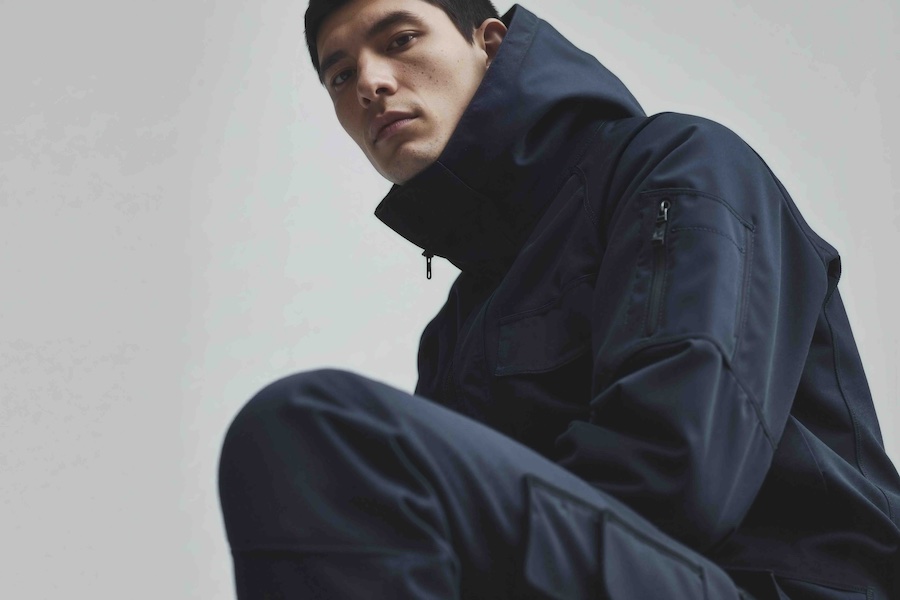

Enhanced Black Intensity

That’s why the traditional dyeing process was reimagined — with a forward-looking result: the new dyeing method creates a significantly deeper, more uniform black while also reducing production time.

The innovative finishing process prevents the typical fading along edges and seams. Tests show that the color remains stable, even after numerous washes. Customers are already impressed: the new Getzner black appears richer, more refined, and visibly more durable than comparable products.

Find Getzner at Milano Unica from July 8 to 10, 2025: Hall 2, Booth A19.