#Dyeing, Drying, Finishing

New expertise in energy and environmental technology for textile finishing

In order to be even better prepared for this and to be able to provide customers with comprehensive advice, BRÜCKNER has bundled its personnel capacities in a new “Environmental and Energy Technology” department headed by Mr. Andreas Troscheit. This area includes all heat-recovery and exhaust air cleaning systems. Mr. Troscheit has already been responsible for the Technology Center in Leonberg and for the entire technical application advice for three years.

In environmental and energy technology, Mr. Troscheit is now supported by Mr. Tobias Keitel and Mr. David Knies. Mr. Keitel focuses on the distribution and design of these systems, while Mr. Knies specializes in software and control. This also includes the ExperTex simulation tool. This intelligent software, which is available for all new machines, enables customers to increase their production output and reduce energy consumption. Depending on the year of manufacture, this tool can also be retrofitted to older lines.

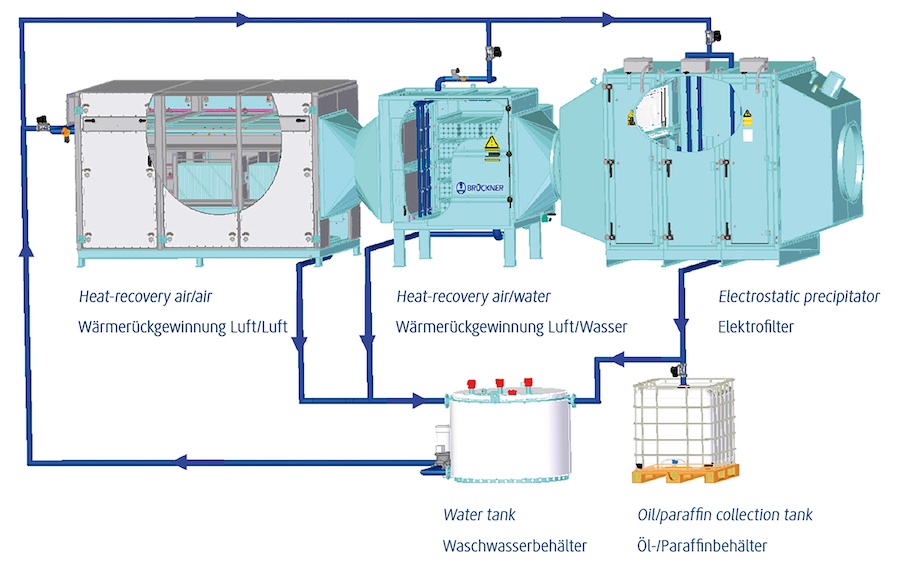

BRÜCKNER's product portfolio in the field of environmental and energy technology is very extensive. The various units for heat-recovery and exhaust air purification are available individually or as a fully integrated system. Thanks to their modular design, these systems can be individually adapted to any customer requirement. Depending on the process, individual units can be flexibly switched on or off.

Newly developed automatic cleaning systems ensure additional energy savings, a significant reduction in maintenance and personnel costs, a longer service life for the filter modules and consistently good filter separation performance. The cleaning programs can be freely configured and the cleaning intervals can be individually controlled so that there is no need to interrupt ongoing production.

BRÜCKNER is the only supplier on the market who can offer all heat-recovery and exhaust air cleaning components from a single source. The newly established energy and environmental technology team combines all the advantages for you as a customer: state-of-the-art technology, expertise and years of experience. You can benefit from this and make your textile finishing sustainable and future-oriented.