#Dyeing, Drying, Finishing

GtA and Monforts welcome the return of global exhibitions

This is great news for both textile finishing technology specialist Monforts and one of its major customers, GtA.

Despite significant ongoing obstacles to global travel, ITMA 2023 somehow managed to overshadow the previous ITMA held in Barcelona exactly four years before it in 2019, attracting over 111,000 visitors to Milan in Italy over its seven-day run.

Turbulence

The four years separating the two ITMA events have, of course, being somewhat turbulent, largely due to the Covid-19 pandemic, so the success of ITMA 2023 was very much to the satisfaction of Monforts, which reported hundreds of visitors to its stand over the course of the seven-day show.

“We couldn’t believe how busy ITMA in Milan was,” said Monforts marketing manager Nicole Croonenbroek. “The enthusiasm took us completely by surprise and we’re now following up on so many potential projects that were discussed there.”

For GtA, which specialises in technical textiles for the digital printing market, events such as ITMA 2023 opening up again are even more of a boost.

“Around 70% of our business is related to trade fairs or major public events such as sports, music and theatre performances, so we are extremely pleased to see the world of large-scale international shows opening up again,” explained GtA Managing Director Andreas Niess. “During the pandemic we had to go on short-time work for six months, but overall we survived well and have continued to develop new products and also meet new requirements for our highly specialised textiles.”

Fault-free substrates

Before the pandemic, a new standard in pure white, 100% clean and fault-free textile substrates was already being demanded to meet the rapid growth in digitally-printed banners and hoardings – often referred to as ‘soft signage’ – that are extensively used for advertising at exhibitions and public events.

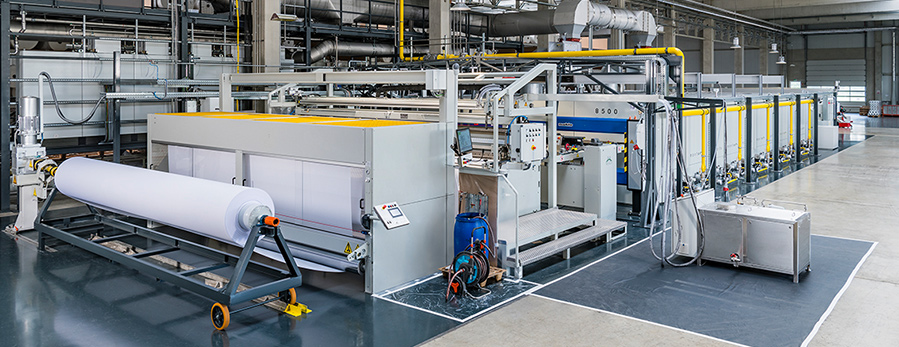

In response to this demand, GtA (Gesellschaft für textile Ausrüstung) was formed in 2016 and erected a purpose-built plant on a greenfield site in Neresheim, Germany with the aim to invest into a sustainable and environmental protective production site.

The plant was first equipped with a fully-automated 72 metres long installation comprising a washing machine integrated with a 3.6 metre wide, seven-chamber Monforts Montex stenter, purpose-built at Montex GmbH in Austria

Building on the success of this installation, the company has subsequently installed two more Montex lines – both with an expanded working width of 5.6 metres – along with a six-chamber unit for further washing processes and a five-chamber line for coating.

Smooth surfaces

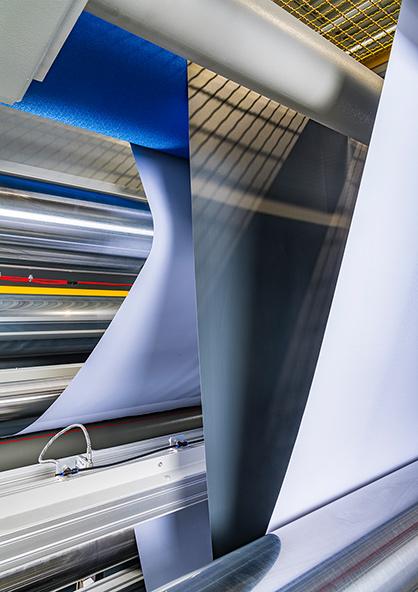

The substrates of choice for digital printing are 100% polyester warp knits which have extremely smooth surfaces. This has become increasingly critical due to the general move away from PVC coatings which were standard in the past.

In addition, the GtA substrates are resilient and allow excellent take-up of inks and vibrant colours and clear and precise images to be achieved with digital printing techniques. The knitted construction also has the advantage of elasticity, which is a plus in terms of flexibility for installers.

GtA now finishes rolls in sizes of between 1,500 and 2,000 metres directly on the Monforts stenters, and after final inspection converts them into rolls with lengths of 75, 100, 150 and or 200 metres, all fully labelled and packed.

Quality

“Happily, we are now back to running 24 hours a day to meet unprecedented demand from the digital printing market, and we are planning further investments in Monforts technology,” said Niess. “Our top priority is always quality, followed by achieving energy savings, and we will continue to be at the forefront when it comes to new technologies, equipment variants and procedures. In addition, the requirements for our wide width materials are increasing.”

As the width of a fabric increases, he explains, its movement through the stenters, both in width and especially in length, becomes more difficult as there is inevitably more longitudinal tension put on the textile.

“It is a big challenge to achieve the desired diagonal and arch distortion as well as the stretch/elasticity, and any crooked stitch on the textile can be seen later after printing, so has to be avoided at all costs,” Niess explained. “We are currently investigating the preliminary stages of warp knitting in order to further influence fabric construction and potential additions to the Monforts finishing lines based on our experience to date. I have to say that the Monforts after-service has been absolutely perfect and there has been no shortage of quality, expertise and service on which we have drawn.”

As far as energy savings are concerned, the company employs various heat recovery systems for its hot waste water, with process exhaust and burner exhaust air integrated in an overall heat exchanger and accumulation system.

Going further, GtA is aiming to become Germany’s first climate neutral textile plant by 2025, via a planned combination of wind turbines, PV systems and hydrogen heating – the latter an area that Monforts is currently investigating with partners in the three-year WasserSTOFF project, launched in November 2022 with sponsorship from Germany’s government.

“Everybody knows that textile finishing is a high energy consuming process,” says Monforts Managing Director Gunnar Meyer. ”To make this process more efficient, Monforts already offers several solutions, but as a technology leader we are also rising to the challenge of exploring alternative heating options to be ready for the future. The experience and know-how of our valued customers such as GtA will greatly accelerate the new journey we are on.”

Special videos of the GtA production site an the Montex stenters can be viewed on youtube at https://youtu.be/FsosEBgN838 and https://youtu.be/4tJzVlJWvLo

Meanwhile, Monforts is looking forward to meeting customers again at two further major exhibitions in 2023 – at Techtextil India in Mumbai from September 12-14 and at ITMA Asia + CITME from November 19-23.