#Dyeing, Drying, Finishing

Effective measures for reducing energy consumption and purifying exhaust air on textile finishing machines

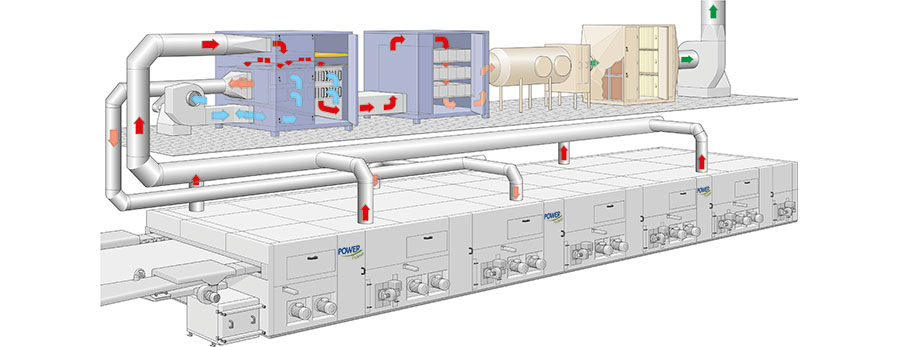

In order to increase the energy efficiency of lines, heat-recovery systems have to be used in addition. These use the exhaust air heat of the production lines for heating fresh air or water. For this purpose BRÜCKNER has for more than 30 years proven and highly efficient ECO-HEAT lines in its program.

The first line stage is usually an ECO-HEAT heat-recovery system air/air (Pic 2). Here, by means of plate or tube heat exchangers, the exhaust air heat is indirectly transferred to cold fresh air, which is then fed back into the drying process. This increases the drying capacity and reduces energy consumption. Of course, ambient air can also be heated with this system, especially in colder countries, thus relieving the building heating system.

An ECO-HEAT heat-recovery system air/water (Pic 3) is often used as a second stage. The exhaust air heat is transferred to water through heat exchangers. The heated water is then used in other textile processes or is also used to heat buildings, thus reducing energy requirements elsewhere. Through heat-recovery, the exhaust air from a drying line, which is contaminated with spinning oils, kerosenes, avivages or chemicals, is already cooled down considerably, causing the pollutant particles to condense on the heat exchangers and be separated out. Over time, however, deposits form on the heat exchangers. Integrated steam cleaning, while not 100% clean, keeps the heat exchangers operational for an extended period of time.

Every few weeks, the handy heat exchanger modules can simply be removed for cleaning and replaced with clean replacement modules. The dirty modules can be cleaned easily and efficiently in an ultrasonic cleaning bath. Afterwards, the cleaned heat exchanger modules can be used again immediately.

If in addition to the heat-recovery an exhaust air purification is of interest, BRÜCKNER offers with its ECO-AIR products a modular system for the compliance with existing exhaust air regulations, e.g. the German TA-Luft. Here the second or third system stage after the ECO-HEAT heat-recovery can be an ECO-AIR exhaust air scrubber which cools down the exhaust air further and binds oil-containing pollutants in its closed water circuit. Due to the sophisticated design of the exhaust air scrubber, very little wastewater is produced. The oily substances separated from the exhaust air are separated from the water by an oil skimmer and disposed of separately. After this, an ECO-AIR electrostatic precipitator can ensure that even the finest aerosols are separated from the exhaust air after the exhaust air scrubber. This also causes the visible smoke above the outside chimney to disappear and the exhaust air odor to be reduced to a minimum.

If this is still not sufficient for some special processes, an additional bio-filter can be installed downstream. This is a simple and cost-effective method of cleaning exhaust air containing odorous substances and VOCs. Microorganisms on carrier material in special biofilter containers convert organic contaminants into carbon dioxide with the aid of oxygen. In addition, organic molecule chains can be broken down in a UV light reactor by intensive UV light irradiation of the exhaust air, and oxygen can be converted into active ozone. In this way, as in the bio-filter, odours and VOC concentration in the exhaust air can be minimized.

With this proven BRÜCKNER ECO-AIR exhaust air treatment system, prescribed emission limits can be reliably complied with. The investment expenditure as well as the operating costs are clearly lower compared to other processes, as e.g. a thermal afterburning system. To solve your exhaust air problems BRÜCKNER has also a small miniaturized exhaust air cleaning test line (Pic 4) which takes a partial flow of the exhaust air over a certain period of time and cleans it by means of the modules described above. At the same time the cleaned exhaust air is analyzed by means of gas sensors. As a customer, you will receive a test report on the feasible purification performance, based on the processes run during the test phase.

With this methodology, it is possible to test in advance how the exhaust air behaves with regard to possible separation effects and whether the prescribed exhaust air limits can also be complied with. With such a modern, multi-stage heat-recovery and exhaust air purification system, a very high energy efficiency is achieved, since a large part of the exhaust air heat or exhaust air energy can be recovered. Moreover, thanks to BRÜCKNER's ECO-AIR exhaust air cleaning system, the exhaust air is effectively cleaned. These systems can also be retrofitted to third-party lines and contribute to a more sustainable and resource-saving production.

Would you like to save energy and/or clean your exhaust air? Contact us - we will be happy to advise you and show you the possibilities and limits of our ECO systems. We will also provide you with ideas for further savings through improved process conditions. Investing in such advice not only saves production costs but also reduces the CO2 footprint of every finished textile.