#Dyeing, Drying, Finishing

MonforClean brings big savings for Albarrie

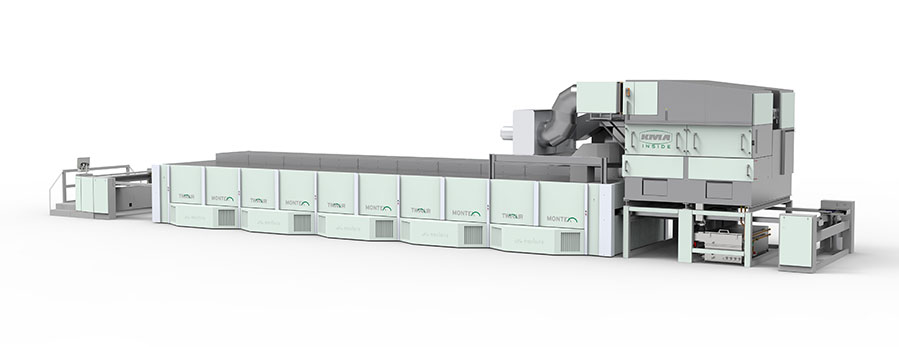

With the new three-chamber Montex stenter at its plant in Barrie, Ontario, the Canadian company is treating specialised needlepunched nonwovens up to 4mm thick. These have applications in a wide range of filter media and performance fabrics.

The new Montex is enabling Albarrie to heat set and dry its materials to produce denser, higher quality fabrics which can also be finished and delivered to customers more rapidly.

Across timezones

It took a crew of skilled millwrights, electricians and product specialists to build the line which was delivered in 11 shipping containers to Albarrie’s production facility. The line was originally scheduled to be fully operational in the Spring of 2020, but the ongoing global Covid-19 pandemic inevitably led to several delays during the start-up and commissioning process.

“Through the challenges of the pandemic, Albarrie staff worked remotely across time zones with Monforts technologists and product specialists to access and configure the machine and run it through a rigorous testing schedule prior to launch,” said Kevin Horner, Albarrie’s Director of Operations.

Assistance closer to home also came from PSP Marketing, which represents Monforts in North America from its base in Charlotte, North Carolina, and reports that there is currently a push for the replacement of stenter frames in the USA.

“There’s a move by a number of our customers to bring more manufacturing back to North America which is definitely a benefit to us,” said PSP vice-president Alex Franco. “And the trend to smaller lot sizes and speed to market is something at which the latest Monforts technologies excel.”

Energy savings

The Albarrie Montex line’s MonforClean capabilities include an air-to-air cross flow heat exchanger and an electrostatic precipitator providing the ability to purify the exhaust air and to recover energy to a maximum of 22,500 cubic metres of air per hour, resulting in a radical reduction in the conventional heat supply required. The MonforClean was developed in cooperation with partner KMA Umwelttechnik, based in Königswinter, Germany.

The fully automated system is powered by a Siemens SPS S7 controller and KP 700 touch panel from which the recycled energy can be continuously monitored and savings calculated.

“The further integration of a washing system which automatically cleans the heat recovery and the exhaust air filter is a serious benefit to US manufacturers because the labour costs for the normally manual cleaning work is so high,” said Franco.

“This is an exciting time here at Albarrie and this new Montex stenter will ultimately open new doors for our business,” said Horner. “We have noticed significant improvements in many areas compared to our old unit, such as the cleaning access and the ability to easily clean, which reduces down-time, while the efficient burners and exhaust system allow quicker start up and cool down periods. In addition, more controllable features allow for increased quality control and the air filtration system reduces smoke and pollutants, keeping pollutant-free air in our neighborhood.”

The three-chamber Montex stenter is fitted with the latest Monforts Qualitex 800 PLC control system with WebUI, providing ease of operation, a full operating cost overview and maintenance monitoring.

“The new stenter has been very easy to learn for the operators,” Horner said. “It is easy to monitor and the controls are simple and easy to understand. While reviewing the requirements for the new machine, energy savings were part of our OEM score card. Energy costs are rising, and with carbon taxes being implemented, having our stenter use natural gas will result in energy savings. We are still early in the process of reviewing the consumption data from the new unit compared to the older unit, but currently, the early data indicate that we are consuming on average the same amount of energy, but achieving 1.5 times the amount of BTUs per hour for the same consumption. Most importantly, all of our products run without problems.”

“This was a big investment for Albarrie, but it was an investment for the future, one that will ensure we have the capability to remain competitive in the fabricated textile market for years to come,” added Executive Director Margaret Driscoll.