#Dyeing, Drying, Finishing

Delivering solutions for today’s manufacturing needs

Whether its fiber, yarn or fabric dyeing, Thies machines utilize soft-flow mechanics that help impart superior hand-feel and uniform appearance of the finished fabric. In the case of fabric dyeing, pathways are shortened and contoured to follow smooth profiles, minimizing surface abrasion and tension. Likewise, yarn dyeing machines incorporate gradual ramping of pressure within yarn packages for uniform bulk and texture during dyeing and drying. The result is high throughput speeds without sacrificing end-product aesthetics and quality.

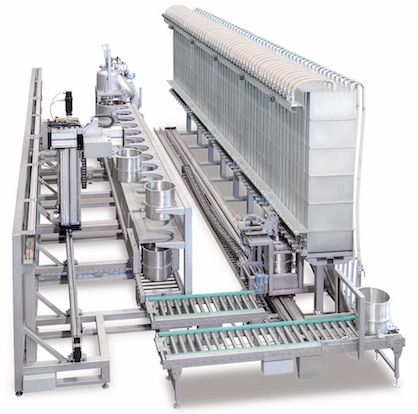

With labor shortages stifling the growth of domestic fabric producers, the drive toward automation cannot happen fast enough. Thies offers a suite of labor-conserving options that can be used in isolation or combination. Customized examples include automated dye weighing, dissolving, and distribution; hands-free dispensing of auxiliary chemicals to dye machines or blending tanks; and machine controls that seamlessly tailor production parameters according to the textile quality and lot size. Machines are optionally networked for ease of managing and monitoring production.

At the core of Thies’ innovations is environmental stewardship of natural resources. In addition to reducing water consumption, benefits include reduced effluent, and up to 50% reduced TDS (total dissolved solids) in dye bath effluent compared to conventional systems dyeing cotton. Furthermore by readjusting the used amount of electrolyte in the dyebath, it is possible to achieve higher dye fixation rates and thus use less dyestuff. Another example is the energy recovery system reduces greenhouse gas emissions. Dyehouses experience 20+% savings in energy cost, and often witness paybacks less than twelve months. Thies is also enabling the use of electricity derived from green energy sources (solar and wind) by designing machines that can, optionally, be heated electrically rather than with steam produced by burning fuels.

The bottom line is Thies gives manufacturers the tools and support needed to meet today’s challenging demands for superior quality, lower cost, and a smaller environmental footprint.

Please join Thies at Techtextil (Booth 1515), or reach them at h.sullivan@thies.group or (803) 366-4173.