#Dyeing, Drying, Finishing

New webshop for spare parts and components

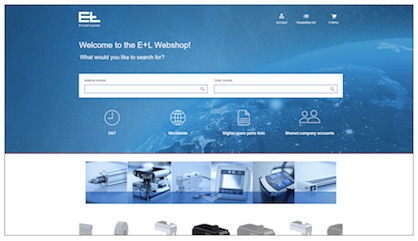

More than 20,000 products are available through this new sales channel. In addition to the classic spare parts, other products such as actuating drives and all E+L sensors are available, which can also be parameterized according to customer specifications prior to delivery. "We are very pleased to now be able to offer our customers all over the world this new possibility to place orders quickly and easily around the clock, seven days a week", explains Dr. Michael Proeller, CEO of the group of companies specializing in automation and inspection technology. "The online shop is a key component of our digital strategy, in which we have invested a great deal to provide our customers with the best possible support, especially in these difficult times".

To help customers find the products they need quickly, the web shop offers extensive search options: material numbers, order numbers and digital spare parts lists can be used for finding products. Any number of employees of a company can use a shared company account for their orders. The address of the shop is www.e-l.shop. There is an English and a Chinese version.