#Digital Printing

Kornit Digital presents the future of on-demand, sustainable production – from creation to order and shipment - at FESPA 2022

The company is set to challenge the digital textile production status quo with a first-of-its-kind experience at FESPA Global Print Expo 2022, May 31st through June 3rd with an integrated showcase of its latest innovations of industry-first solutions at Hall: 27, Stand: 27-D60. These solutions present the future of new possibilities for high-quality and productivity of on-demand, sustainable production, including the merging of the physical and virtual worlds.

• Kornit Showcases the New Standard of Quality and Productivity in a Groundbreaking, Single Step Digital Textile MAX Production Systems - All in One Place

• For the First Time at FESPA, Entire Ecosystem of Digital Textile MAX Production Systems and Powerful Workflow Solutions on Display, Showcasing the Full Pixel-to-Parcel to Doorstep Experience

• Attendees Experience New Possibilities as Physical and Virtual Worlds Come Together, Unlocking the Potential for On-Demand, Sustainable Production

• Download the Kornit Digital Press Kit to Learn More:

https://kornit.com/lp/press/press-kit-event-fespa-berlin/

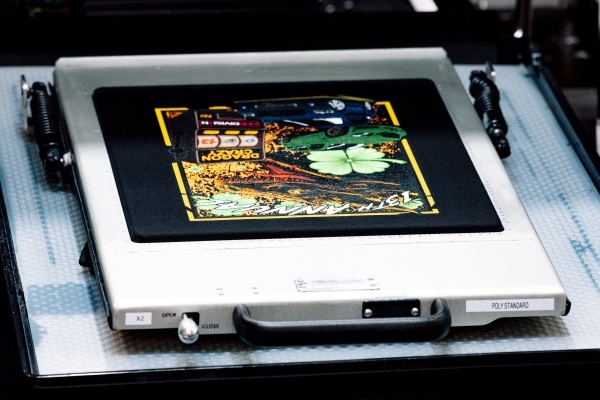

Throughout the four-day industry event in Berlin, Germany, the company will engage attendees with its portfolio of single-step, digital direct-to-garment (DTG) and direct-to-fabric (DTF) production solutions based on its game-changing MAX technology. These solutions allow fulfillers and brands to enjoy unmatched retail-quality applications, including 3D, vinyl, screen, dye sublimation, and embroidery effects – all in one solution. Integrated with the powerful KornitX Workflow Solutions, customers can now take textile production from pixel-to-parcel to doorstep for a streamlined workflow process. Furthermore, Kornit is setting the pace across industries - spanning apparel, sportswear, home décor, accessories, custom fabrics, and other diverse, high-fashion textile – with its end-to-end digitized production workflow and lean, agile and profitable just-in-time fulfillment. Kornit enables its customers to establish fast and integrated production workflows for superior quality and durability with a smaller physical footprint.

To enhance profitability and growth, fulfillers can capitalize on the most advanced technology and ecosystem to create new business relationships and answer opportunities quickly, while brands can partner with this growing network of Kornit-enabled producers through Kornit’s unique Global Fulfiller Network and establish demand-driven fulfillment models closer to the end consumer – eliminating waste and supply chain vulnerability.

“At Kornit, our vision is not only to produce superior technologies but also create better experiences for our customers, as well as their customers, whether it takes place in the physical world, the virtual world – or both,” said Omer Kulka, Chief Marketing Officer at Kornit Digital. “Kornit is committed to helping the industry eliminate waste to answer the sustainability imperative, while settling for nothing less than graphic brilliance and the most rigorous quality standards. Our lineup of revolutionary MAX technology-driven production systems and innovative workflow capabilities convey that commitment – and we encourage those at FESPA to see it live.”

The full suite of Kornit’s game-changing innovations on display at the event include the Kornit Atlas MAX, Kornit Atlas MAX Poly, Kornit Presto MAX, KornitX Workflow Solutions, and Tesoma textile curing solutions – all showcasing streamlined end-to-end digitized production workflow. For full details of all Kornit’s solutions on display – for the first time in Europe - please see “Note to Editors” below.

“As FESPA returns to a large-scale event, we are excited to showcase our continued work alongside brands, creators, and fulfillers to solve their most difficult textile production challenges. Kornit’s relentless research and development, vision, diligence, and innovation will create a visionary experience for FESPA attendees – opening eyes to what digital can be, how it transforms the industry, and new ways to unleash creativity with the quality, durability, accessibility, and performance our marketplace desperately needs,” said Chris Govier, President at Kornit EMEA. “With Kornit’s latest innovations of sustainable, on-demand offerings, there’s nothing keeping our network of customers, partners, designers, and brands from achieving their own vision and driving the much-needed disruption the market requires.”

Don’t miss Kornit’s exclusive press conference on May 31st at 5pm local time taking place in the Press Conference Room in Hall 6.3 and the dedicated press demo tour on June 1st at 10:00 am at the Kornit booth at Hall: 27, Stand: 27-D60. For press to book an appointment with Kornit Digital at the FESPA Global Print Expo 2022, please contact Ingrid Van Loocke at ingrid@pr4u.be.

To join Kornit’s daily demo tours to experience the full pixel-to-parcel workflow on the Kornit booth, visit our booth at Hall: 27, Stand: 27-D60, or reach out to Maximiliane Jona to book a private tour.

For more information and materials on Kornit’s complete ecosystem of end-to-end digital textile production solutions, please visit our digital press kit.

https://kornit.com/lp/press/press-kit-event-fespa-berlin/