#Denim

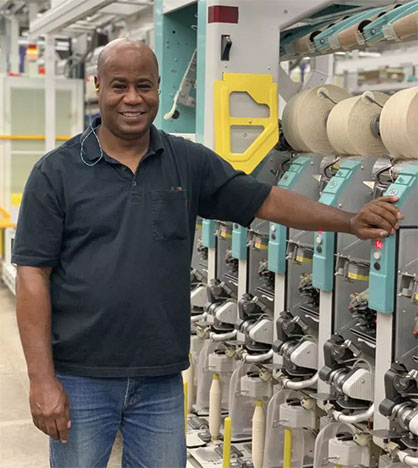

Loepfe interview with Steve Maggard President CONE DENIM LLC, USA

From performance denims and superior S Gene® technology to vintage re-creations of their Cone® Deeptone Denim reaching back to the early 1900s, Cone Denim offers unique collections of performance, stretch, selvage, and natural indigo denims crafted out of their very own Cone® 3D R&D incubator.

With mills strategically located in China and Mexico, Cone Denim is excellently positioned to make a strong contribution to their long-term strategy of providing customers with innovative and market-driven denims and services from a global network of manufacturing platforms.

Promoting sustainable practices in its operations and development of new denims, Cone Denim delivers unparalleled expertise and advanced denim capabilities that service and inspire the global market.

As part of Elevate Textiles, a distinguished collection of global brands, Cone Denim is redefining the world of textiles by providing global solution to a constantly evolving industry.

Interview

Loepfe: Quality has always been a key factor for Cone’s success, why did you put all on it from the beginning?

SM: Clearing technology is a key component in achieving yarn quality. Loepfe has been a key vendor for Cone Denim in yarn clearing technology, providing advanced flexible clearing capability.

Loepfe: To produce the reliable quality that the market demands for always means investing in the latest technologies and knowing the market trends. What are your inducements for this?

SM: We have chosen Loepfe for the reliability and flexibility in the clearing technology. The ability to clear fancy yarns and monitor splicing quality are key factors that we consider when we chose our clearing technology.

Loepfe: Cone Denim has created a new global standard for stretch denim – The S Gene® dual-core technology. Can you tell us more about its inventor(s), the specific characteristics and the resulting benefits of it?

SM: The S Gene technology was invented by our product development area. Lead developers included Allen Little, Cone Denim’s Director Product Development; Reuben Hart, Technical Support Specialist; and former Cone Denim developer Ralph Tharpe, who were all part of the original team that worked to create the revolutionary S Gene® technology. S Gene® technology changed the performance of stretch denim creating not only superior stretch but never before seen recovery, eliminating baggy knees and waistbands and improving fit and comfort throughout the day. The advanced S Gene® technology led to tremendous growth of stretch technology in denim.

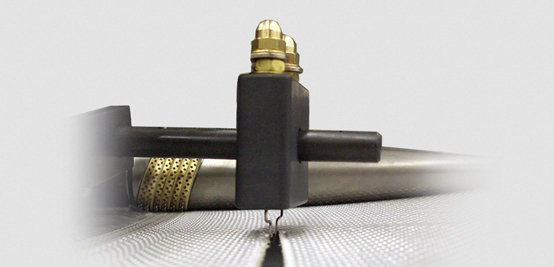

Loepfe: In your winding process, you build on Savio Polar machines and trust on Loepfe Zenit+ yarn clearers. What are the main challenges in manufacturing dual-core stretch yarns and what benefits did you achieve by integrating Loepfe yarn clearers?

SM: Dual core stretch yarns are manufactured using both normal and slub yarn patterns. The ability to monitor and clear both yarn types with precise clearing technology is a must for our quality standards. Splice monitoring and quality clearing are of the utmost importance and the Loepfe technology allows us to monitor and remove any splices that do not meet our quality parameters.

Loepfe: Denim is a huge trend and enjoys a constantly growing demand. Because of that, more and more new companies are entering this sector. How do you see the development of the denim market over the next 2-5 years?

SM: We feel that denim customers are moving to a more sustainable approach for both the manufacturing of denim and garments. We at Cone Denim have a long history of sustainable manufacturing spanning over 128 years. We continue as a global leader focused on developing and investing in technologies to improve our manufacturing processes and minimize our environmental impact. We know this is increasingly important to our customers and we are proud to be a valued partner in achieving their innovation and sustainability goals.