#DOMOTEX 2024

Create original designs and enter new markets with ALPHA carpet systems

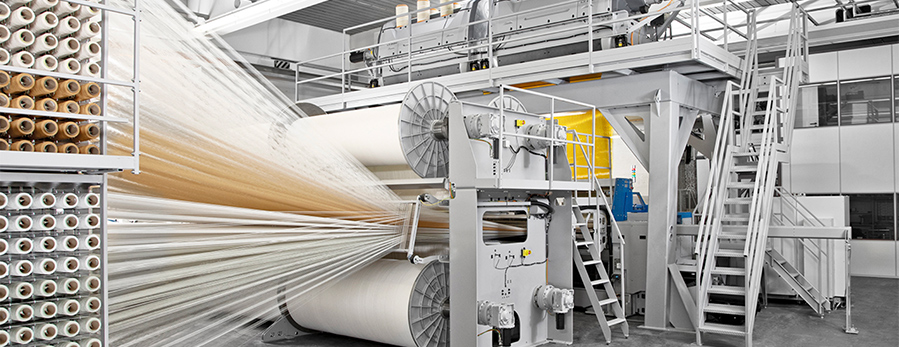

Stäubli carpet weaving systems offer a high degree of flexibility that weaving mills can use to secure their market position and operate at the forefront of the world's best carpet producers.

The ALPHA series – a solution for every type of carpet

With the ALPHA machine line-up, Stäubli offers optimal solutions for any desired carpet design and quality level, whether rug or wall-to-wall carpet. Weaving mills can adopt a broad market approach and produce all sorts of carpets, even those for heavy use as in the transport or contract sector.

ALPHA 580 UNIVERSAL – State-of-the-art technology for creativity and energy savings

The latest model in the series was presented at ITMA 2023 in Milan. The ALPHA 580 UNIVERSAL boasts great versatility in design options including cut pile and flat weave, pattern on the ground, weft patterning as well as reverse, sisal, and high pile. Carpet manufacturers and their staff enjoy not only the compactness of this weaving system but also its easy and highly reliable operation. The Jacquard machine handles the pile weaving. Here, the LX2494 model was presented. It is equipped with sophisticated NOEMI electronics architecture by Stäubli. NOEMI ensures high-speed data transmission and signal-transmission stability. Up to 25,600 hooks can be operated without reducing the weaving speed. That’s just one of the many technical highlights, one which also provides energy savings. In the area of basic weaves the weaving system offers a new compact electronic rotary dobby. The functional principle of this shed forming solution is the renowned Stäubli rotary principle.

The Stäubli Group stands for worldwide service

The ALPHA 580 UNIVERSAL and the other models in the ALPHA series not only feature many technological highlights but are backed up by intensive Stäubli services including practical consulting prior to purchasing, training before weaving, and support services even years after the purchase. Leading carpet manufacturers around the world rely on ALPHA machines and these services from the Stäubli Group.

Meet Stäubli at Domotex at Booth E43 in Hall 5!