#Composites

MODEC and Toray jointly develop FPSO and FSO repair technique using CFRP Patch

FPSO and FSO repair services provided by MODEC, a general contractor specializing in engineering, construction, operation, and maintenance services of offshore oil and gas vessels, will utilize this CFRP patch technique for pitting corrosion repair from 2024.

The American Bureau of Shipping (ABS), which provides classification services for marine and offshore assets, approved this technique for repairing areas with diameters of up to 300 millimeters that have suffered damage from pitting corrosion.

FPSO and FSO maintenance takes place without interruption to oil and gas production. Accordingly, developing a repair technique that facilitates the efficient deployment of materials and equipment offshore and does not involve hot work is vital. These considerations prompted MODEC and Toray to jointly develop a vacuum-assisted resin transfer molding (VaR™) process1 for CFRP repairs in 2020. ABS approved applying CFRP to steel to restore its mechanical strength.

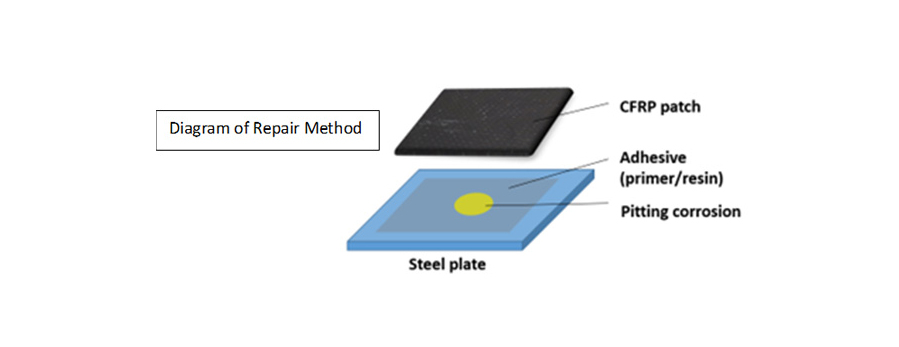

While excellent for repairing large corrosion areas, this process was less suitable for pitting corrosion repairs. The new CFRP patch technique is a more straightforward and more effective solution in such cases. It only requires bonding prefabricated CFRP patch flat plates over pitting corrosion, thereby reducing the workforce by half and improving lead times (referring to onsite times compared with the VaRTM process and excluding materials procurement lead times).

This technique eliminates the need for vacuum pumps and other equipment and streamlines the process of transporting reinforcement materials and construction tools onboard. Moreover, this technique ensures minimal disruption in oil and gas production because it eliminated the need for hot work.

Together with Toray, MODEC will cater to the diverse corrosion repair needs of FPSO and FSO operators by offering the in-situ VaR™ technique for extensive repairs and the CFRP patch technique for localized repairs. The two companies will continue to develop repair technologies for these vessels to promptly address market needs while tackling environmental and other social issues to contribute to a sustainable economy.

Profile of MODEC, Inc.

1. Main business: Owner/operator and EPCI (Engineering, Procurement, Construction and Installation) general contractor of floating production systems including FPSO and FSO

2. Headquarters: 3-10, Nihonbashi 2-chome, Chuo-ku, Tokyo

3. Founded: December 1968

4. Representative: Takeshi Kanamori, President & CEO

Profile of Toray Industries, Inc.

1. Main business: Manufacturing, processing, and selling fibers, plastics, and other basic materials

2. Headquarters: 1-1, Nihonbashi-Muromachi 2-chome, Chuo-ku, Tokyo

3. Established: January 1926

4. Representative: Mitsuo Ohya, president and representative director

Note 1.

See the following related releases:

MODEC obtains Approval by ABS for New Offshore Repair Method for Hull Structures of Floating Production Facilities

https://www.modec.com/news/2020/20201223_pr_CFRP.html

Toray Develops FPSO and FSO Repair and Reinforcement Technique with MODEC

https://www.toray.com/global/news/article.html?contentId=fui2dsd5