#Composites

Solvay partners with iCOMAT, developers of game changing composite processing technology

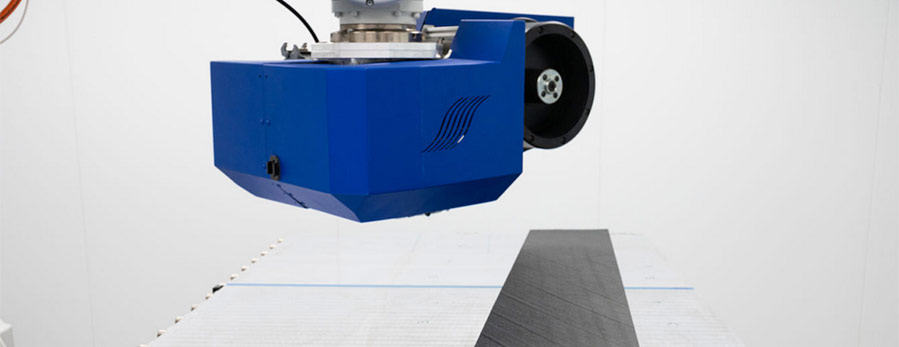

Solvay is partnering with Bristol, UK based start-up iCOMAT who has developed Rapid Tape Shearing (RTS), a truly disruptive material deposition technology that will revolutionize the design and manufacture of composite parts, answering the industry’s need for lighter and more cost efficient composite structures.

RTS is the world’s first industrial manufacturing process that enables defect-free steering of wide composite tapes, enabling precise tailoring of the fiber orientation at any point of a composite material part and providing unprecedented levels of structural efficiency. This means less material deposited enabling lighter and more cost effective parts than ever before.

Steering makes it possible to control fiber orientation during forming, reducing forming-induced defects and improving structural performance. By combining RTS-made steered blanks with Solvay’s Double Diaphragm Forming (DDF) technology and rapid curing prepregs, reduced part weight and takt time can be achieved, providing the composite industry with solutions to achieving high volume part production.

“Solvay is focusing on accelerating the industrialization of composites through the development of high rate materials and processing technologies”, said Marc Doyle, EVP Composite Materials Market, Solvay Composite Materials Global Business Unit. “This partnership with iCOMAT enables us to bring to market a groundbreaking solution that, when combined with Solvay’s technologies, will change the way our customers approach part manufacturing. I am looking forward to seeing where this takes us”.

Solvay and iCOMAT will work together to accelerate RTS’ commercial exploitation using a new RTS pilot manufacturing cell to be operational in 2024 at Solvay’s Composite Material Application Center in Heanor, UK.

“Our vision at iCOMAT is to provide our customers with the lightest components possible, rapidly and at a low cost”, said Evangelos Zympeloudis, CEO of iCOMAT. “Steering can drastically improve structural properties but the only way to achieve our vision is to unlock industrial rates and fully automated production. Our partnership with Solvay is key to that end as we aim to demonstrate the production of complex parts of exceptional structural efficiency. 2024 will certainly be an exciting year!”