#Composites

ITA shows a novel multi-fibre coating system live at the JEC

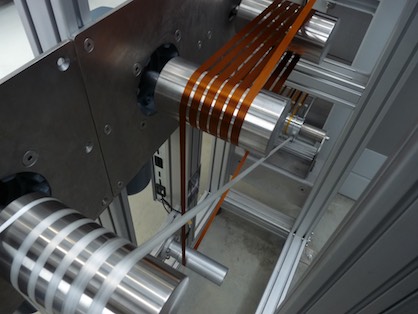

1. Novel multi-fibre coating system live in lab scale

The multi-material fibre coating line coats or impregnates rovings made of various materials and produces TowPregs, also known as pre-impregnated rovings, from thermoplastics and carbon fibres live at the JEC booth. TowPregs can be processed by winding or braiding. They are used in drive shafts in the automotive and the aerospace industry.

The system has a wide range of applications and allows a fast output. With a maximum processing temperature of 400 °C, it also allows high-temperature thermoplastics to be processed and tests with a wide variety of materials on a laboratory scale within one day, thanks to its short preparation times of less than one hour. The current production speeds are 5 m/min, depending on the material used and the configuration of the system. Upscaling to industrial scale is possible as the operating principle has already been validated on laboratory scale.

The plant can process thermosets and thermoplastics, but there are some advantages in processing thermoplastics over thermosets: there is no downstream consolidation process required, there are shorter cycle times and thermoplastics are recyclable.

With this line, TowPregs with circular cross-sections of up to five millimetres in diameter and tape-like geometries of up to 20 millimetres in width can be produced at a production speed of 5 m/minh - depending on the material used and the configuration of the line. The TowPreg produced on the line can thus be seen as a more cost-effective alternative to regularly produced tapes. For further information, please contact max.schmidt@ita.rwth-aachen.de.

2. Carbon fibre production - halving the cost and stabilisation time

One of the core research areas at ITA is the production of carbon fibres. ITA has a continuous pilot-scale carbon fibre production plant with a production capacity of less than one ton per year. Due to its comparatively small size and the resulting low material input, the plant is ideally suited for the development of new stabilisation and carbonisation profiles and the testing of new fibre sizings.

The current main goal of research in carbon fibre production is to shorten the stabilisation time. By developing a novel method the stabilisation time at ITA could be reduced from initially 50 min to 21 min. The resulting fibres are similar to a Toray T700 carbon fibre.

Another approach to reduce the cost of carbon fibres is the use of alternative raw materials such as polyethylene (PE). This can reduce the carbon fibre price by about 50 %. Due to the existing spinning and sulfonation plants, ITA is one of the leading research institutes dealing with the production of cost-effective carbon fibres based on polyolefins. For further information, please contact felix.pohlkemper@ita.rwth-aachen.de.

3. Textile technology and photonics revolutionise joining technology

Carbon fibre-reinforced (CFRP) components are normally assembled by fasteners that are glued into the cured and drilled CFRP component. The integration of the fasteners into a textile preform and an additional curing process to produce the final CFRP component can shorten production process chains and can increase the performance of the joint by at least 50 %. This requires high-precision cut-outs in the textile for the fasteners.

In the NRW-based project CarboLase, funded by OP.EFRE, laser material processing is integrated for the first time into an automated preforming process. A novelty in the process is the use of the material-friendly ultrashort pulsed laser, which processes the textiles without damaging them thermally.

By combining the technologies in a flexible robot cell, just-in-time production of CFRP components with integrated fasteners is now possible independent of component geometry and batch size. With the new process chain, demonstrators were produced fully automatically. A demonstrator in the form of a B-pillar segment with integrated fasteners is shown in the figure above.

This technology was developed by the Institut für Textiltechnik of RWTH Aachen University, short ITA, in collaboration with its partners AMPHOS GmbH, Kohlhage Fasteners GmbH & Co. KG, LUNOVU Integrated Laser Solutions GmbH and the Fraunhofer Institute for Laser Technology ILT. For further information, please contact sebastian.oppitz@ita.rwth-aachen.de.

4. High speed prepreg filament winding: averaging 5 sec. per layer

Filament winding technology, even though it has been established for the manufacturing of tubular composites, is seeing great leaps in the past years. Along this line ITA has been working with many industries, starting from the machine to fibre manufactures. One among these collaborations is with the Muratec, Japan. This has led to a further development of the novel Multi-Filament winding technology. The main advantage is that many fibres (facility at ITA with 48 fibres) can be wound simultaneously. This increases the processing speed by a factor of 50. Furthermore a coverage of 100 % can be obtained in a single pass.

The working speed has been increased further with the development of high quality prepregs through the ZIM project MFWOptiPreg with the company F.A. Kümpers GmbH & Co. KG. The optimised tack (stickness) and fibre breakage, high winding speeds and quality products can be achieved. Filament winding has an advantage of orienting the fibres in the desired direction (0°??<90°).

As an example for quality products, these prepregs have already been tested for pressure vessel and torsion shaft manufacturing. The developed prepreg is already available in the market. Figure above shows a torsion shaft which is manufactured using the developed glass fibre prepreg in a multi-filament winding machine. This is then cured in an oven. Afterwards load distributers are connected using high strength adhesives. For further information, please contact kumar.jois@ita.rwth-aachen.de.

ITA is looking forward to welcoming you at AZL’s joint booth in hall 5A booth D97!