#CINTE Techtextil China 2024

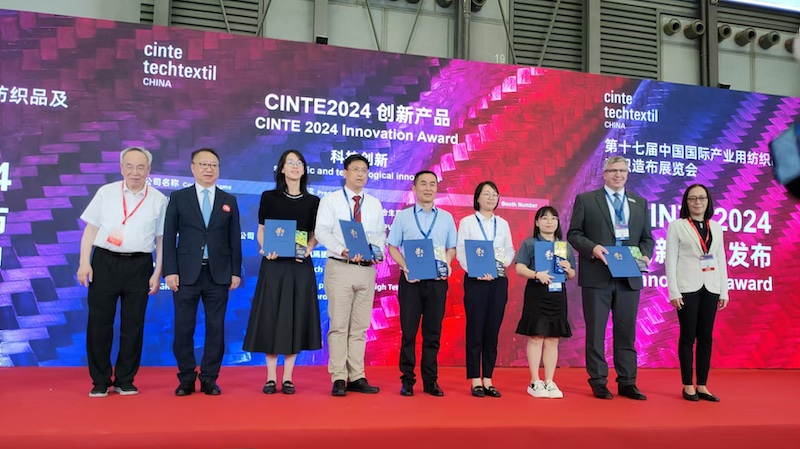

DILO receives award for the new development MicroPunch

For DILO, this meant focusing once again on needling technology for the fine and lightweight nonwoven sector over the last years. The individual elements of the intensive needling technology were re-examined and underwent a complete revision. It became clear that the high production rates could only be achieved using the two-dimensional kinematics of the needle beam from "HyperPunch" or "CycloPunch." The necessary high feed rates of around 50 mm per stroke, coupled with the highest stitching densities to achieve good abrasion resistance, led to a need to significant increase of the number of needles and needle density—almost doubling from approximately 20,000 needles/meter/board to around 45,000 needles/meter/board. It became obvious that ensuring high efficiency also required the careful attention to a quick assembly of the needle boards with needle modules. A completely new approach was needed in the design and construction of the needle boards to enable rapid module exchange and achieve a very high mechanical precision.

Previously, needling technology was primarily used for surface weight range starting at 100 g/m² up to several kilograms per m². The expansion into the range below 100 g/m², and potentially down to 30 g/m², now completes the applicability of needling technology. The intensive needling technology "MicroPunch" opens up an economical field for a wide variety of lightweight nonwoven fabrics that can be produced with a pure mechanical process. The product characteristics achieved, such as abrasion resistance, are comparable to those of hydroentangeld nonwovens, but needled fabrics tend to be more voluminous and more stretchable while offering similar tensile strength values. These special quality characteristics are particularly interesting for applications in hygiene, medicine, cosmetics, and for technological products.

With this new development, the energy required to produce lightweight nonwoven fabrics has been reduced by approximately 75% compared to previous bonding technologies in this segment.