#Associations

Driving innovation in technical textiles, digitalisation and testing

“Our members have been very active over the past 12 months and this has resulted in new technologies for the production of technical fibres and fabrics, the introduction of AI and machine learning into process control systems and significant advances in materials testing,” says BTMA CEO Jason Kent. “There’s real excitement about what can be achieved in 2026 as we look ahead to upcoming exhibitions such as JEC Composites in Paris in March and Techtextil in Frankfurt in April.”

Composites momentum

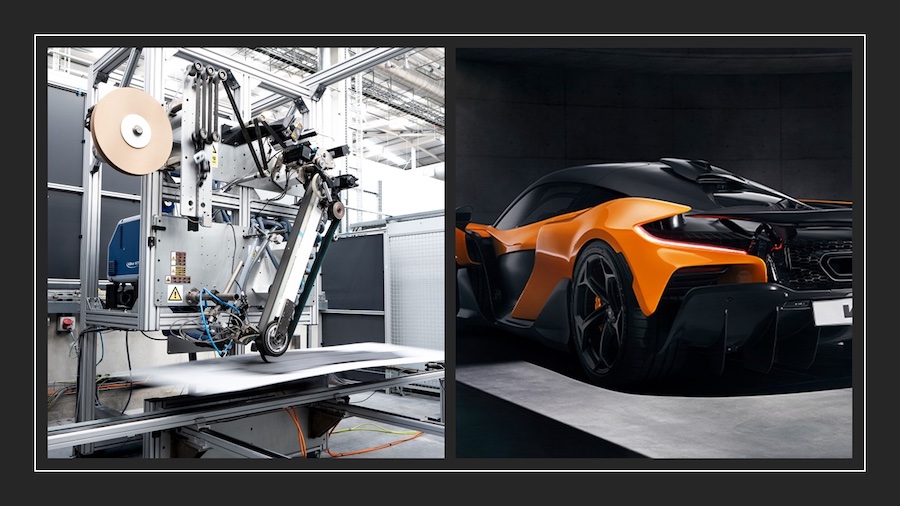

Cygnet Texkimp, for example, has been nominated for a 2026 JEC Innovation Award for its collaboration with McLaren Automotive on the ART rapid tape-deposition system. Capable of depositing dry fibre tapes at up to 2.5 metres per second with exceptional precision, ART reduces scrap, shortens cycle times and delivers structural improvements already being realised across McLaren’s composite-intensive vehicle platforms.

Cygnet is the world’s largest independent manufacturer of prepreg production machinery, alongside a broad portfolio of handling and converting systems for the composites industry.

In addition, the company is licensed to design and build the DEECOM® composite recycling system developed by fellow BTMA member Longworth Sustainable Recycling Technologies. DEECOM® is a zero-emission, low-carbon pressolysis solution that uses pressure and steam to reclaim fibres and resin polymers from production waste and end-of-life composites.

Other BTMA members supporting the composites sector include Emerson & Renwick, which applies deep expertise in print, forming, vacuum and coating technologies to carbon fibre processing, while Airbond is a pioneer in pneumatic yarn splicing for high-value carbon and aramid fibres. Slack & Parr meanwhile supplies high-accuracy gear metering pumps across the manmade fibre market, where they process a wide range of polymers and fibres with uniformity and consistency.

Gel spinning

Further resource savings in high-end fibre processing have been realised by Fibre Extrusion Technology through the introduction of a new process for manufacturing ultra-high molecular weight polyethylene (UHMWPE). The company’s patented solvent extraction system exploits supercritical carbon dioxide.

“Current UHMWPE systems are huge in scale and extremely complex,” says FET R&D Manager Jonny Hunter. “That makes the supply chain inflexible and limits new product development. These disadvantages have been addressed in our new FET-500 series lab and small-scale gel spinning system.”

Quality assurance

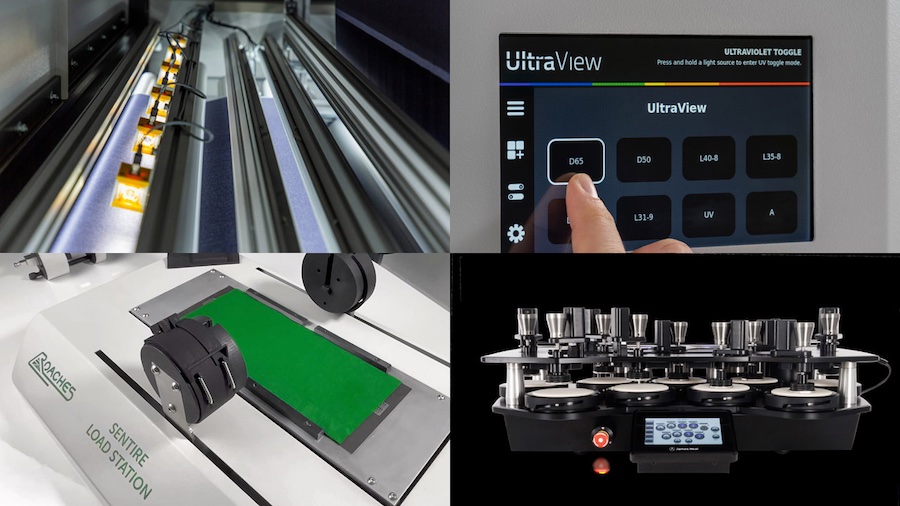

Alongside materials innovation, BTMA members are also reshaping quality assurance via digitalisation and data-driven manufacturing. Shelton Vision has significantly advanced automated fabric inspection with the latest generation of its WebSpector system. Using patent-pending image processing techniques, WebSpector now enables reliable real-time defect detection on complex patterned fabrics, including those subject to distortion, shear or stretch during processing.

Building on its leadership in plain fabric inspection, the Shelton system now adapts to intricate designs such as camouflage and delivers clean, stable images that allow full fault detection at high running speeds. While automotive interiors and one-piece woven airbags remain key applications, WebSpector systems are increasingly being supplied to producers of performance wear, fashion, denim, outdoor upholstery, mattress ticking, window dressings and even carbon fibre composites.

Continuous colour

A comparable shift from intermittent checks to continuous monitoring is taking place in colour management through the work of C-Tex. Traditionally reliant on periodic swatches, mills can now apply laboratory-level colour measurement directly in production.

“What we are doing is taking a lab capability and putting it into production,” says Managing Director Rob Ricketts. Working with Shelton, C-Tex has combined inline defect detection with continuous colour variation analysis, enabling both parameters to be assessed simultaneously.

Importantly, this data is now shared across supply chains. When fabrics reach garment, automotive or furniture manufacturers, downstream users know exactly what they are receiving and whether it meets their requirements.

“This visibility is a big breakthrough,” says Ricketts. “It’s well established in automotive, but now it’s coming to textiles too.”

Intuitive testing

Advanced testing remains another cornerstone of BTMA innovation. James Heal has long supplied advanced textile testing systems and its latest Performance Testing collection focuses on speed, simplicity and intuitive operation for parameters such as airflow and water resiliency. Water repellency testing has similarly been improved with the TruRain system which dramatically reduces wastewater and energy consumption.

During 2025, the company also introduced the new Martindale Motion.

The new nine-station instrument with individual lifting heads now offers the flexibility to run each station independently for carrying out different textile tests simultaneously. Once set up, the Martindale Motion can be left running with the sample holders automatically lifting at the required evaluation points, freeing up the operator’s time to do other work without the need to return until the abrasion or pilling test is fully completed, including overnight.

Colour accuracy is addressed by the VeriVide DigiEye system which provides non-contact colour measurement and digital imaging, enabling objective data capture and rapid sharing across organisations. Recent developments include 100% LED illumination, integrated dust filtration, software-controlled lighting geometry and automated image capture, improving both precision and efficiency.

Tactility challenge

The tactile sensation experienced when touching and manipulating fabric is meanwhile a critical aspect of textile evaluation, but to date has been very subjective. One of the biggest challenges faced by designers and manufacturers is in describing and sharing information about fabric aesthetics before manufacturing, or without the costly and time-consuming process of transporting physical samples.

These limitations are being overcome with the new Sentire fabric handle tester from Roaches International.

“No two people will describe how a fabric feels in the same way and the lack of a common language to describe fabric tactility poses communication challenges across the complex global fashion and textile supply chain,” says Roaches International MD Sean O’Neill. “The Sentire has been developed to allow our customers to objectively measure qualities such as softness, smoothness, drape and stiffness and market response during 2025 has been extremely positive.”

Convergence

Bringing these developments together, Jason Kent sees a clear strategic direction emerging.

“Across the BTMA we’re seeing a convergence of advanced machinery, intelligent software and rigorous testing,” he says. “Our members are responding to today’s challenges around efficiency, sustainability and quality, while laying the foundations for a more transparent, data-driven and resilient textile manufacturing sector. Despite market uncertainty, there is genuine confidence about what lies ahead for British textile machinery and its global customers.”

* Founded in 1940, the British Textile Machinery Association actively promotes British textile machinery manufacturers and their products to the world. The non-profit organisation acts as a bridge between its members and the increasingly diverse industries within the textile manufacturing sector.