#Nonwovens / Technical Textiles

DiloGroup at Techtextil India

The emphasis of the latest equipment components has been laid on improving web quality and uniformity applicable to all bonding processes as well as operation efficiency of the needling line.

DiloGroup enjoyed above-average order influx in all important markets for its machines and installations and had record turnovers in 2015 and 2016. Due to an increase of about 20 %, the overall turnover in 2016 reached a total of around 113 million Euros. This shows DiloGroup’s strong position in the international nonwovens machinery business. The increase has been accompanied by the creation of numerous new jobs. DiloGroup now has around 450 employees. In addition, they have increased assembly space by 3000 m².

As the leading group in the field of staple fibre nonwoven production lines DiloGroup will inform about complete lines presenting the latest developments of all components. The strong demand for DILO production lines is partly due to the increased requirement for needled nonwovens with a yearly growth in consumption of about 6 – 7 %.

Staple fibre production lines start with fibre preparation – opening and blending – from DiloTemafa, card feeding and cards from DiloSpinnbau and end with crosslappers and needlelooms from DiloMachines.

The quality of DiloGroup’s four equipment components, opening and blending, carding, crosslapping and needling, is important to customers. A DILO line represents highest productivity with best web quality. This goes hand in hand with high efficiency as the mentioned four machine components are controlled by central drive and control stations in preparation for the modern requirements of crosslinking and smart production.

Customized lines are engineered, manufactured, delivered and put into operation by DiloGroup.

Service and spare parts supply to support the high efficiency of DILO nonwoven production lines is available worldwide. In addition to information about standard universal lines, they will inform about the latest developments in DILO machines which aim to increase efficiency and productivity by the degree of automation and to improve end product quality.

One example of such innovations is the “Vector 200”, a new crosslapper by DiloMachines which is the first crosslapping machine in the market with an infeed speed of over 200 m/min.

DILO lines are used for the production of nonwovens for all applications including automotive products, floor coverings, synthetic leather, wipes, geotextiles, roofing and filtration.

Considerable progress has been achieved in the processability of special fibres like virgin and recycled carbon fibres for composite materials. Compact special lines for product research, development and production with carbon fibres are available and can be discussed with interested visitors.

A close cooperation with needle manufacturer Groz-Beckert has advanced the development of the needle module technique and the intense needling of light weight nonwovens. Detailed information will be available at the booth.

Numerous fields of application such as filter media, geotextiles, roofing material, floor coverings, other technical textiles and composites require needled nonwovens with high low-load resistance. This is generally achieved by using reinforcing meshs / grids. The DILO HyperTex installation produces a reinforcing scrim which is fed between two needlefelts which are then joined together by a Hyperpunch needleloom.

The aperture size of this scrim can be varied up to 20 x 20 mm and production speed is up to 40 m/min. The HyperTex installation in a working width of 2.5 m is available for presentation and trials in the DILO Textile Research Centre in Eberbach, Germany.

DiloGroup will also inform about carding systems of wide working width and high web speed for water entanglement lines. For this important branch of nonwoven production lines generally have a working width of about 3.8 m and medium web speeds of around 200 m/min. DiloSystems offers special carding systems with working widths exceeding 5 m and resultant web speeds of more than 400 m/min after water entanglement and drying.

Reduced draft between card doffing and winding are essential to achieve a high web uniformity and an acceptable strength ratio in machine direction to cross direction (MD:CD). DiloSpinnbau sets the standard for high productivity with the random roll technology and for best felt homogeneity by low draft. DiloGroup is very successful with these fibre preparation and carding systems in nonwoven production lines with high productivity and quality requirements.

Further important features of these special installations are the fibre preparation from DiloTemafa, the air technique for card suction, filtration and moistening which result in high line efficiency.

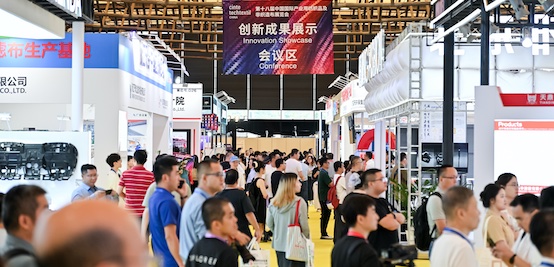

At the Techtextil India 2017 DiloGroup will explain the characteristics of DILO standard and special nonwoven production lines in discussions with international customers.

Visit DiloGroup at Techtextil India, Mumbai – Booth No. B36 from September 13 – 15, 2017.