#ITM 2016

Monforts ‘Thinking Ahead – for sustainable solutions’ at ITM

The new segment of coating machines will also be presented allowing the company to serve the market from a single source with Monforts-made, high class and most versatile coating ranges.

Increased energy savings with retrofitted Eco Booster The Monforts Eco Booster HRC, designed to minimise energy costs during drying and heat setting processes on stenters will be available, for the first time, for retrofitting to existing Montex installations.

By contrast with purely static heat exchanger modules, the new heat exchanger module actually cleans itself during operation; eliminating standstill times for maintenance. The Eco Booster permits a computer-controlled adaptation of the heat exchanger performance to the prevailing waste air stream. This optimised efficiency further reduces the process costs. Eco Booster runs fully automatically so that the operator has no additional duties to carry out. Its automatic cleaning feature means the machine doesn’t have to be stopped during production runs.

New stentering chain A completely maintenance free Montex horizontal stentering chain will be introduced. This new chain type complements the well proven Montex chain systems for horizontal chain return. The new Montex Hybrid Chain will be also available for retrofit to existing Montex stenters.

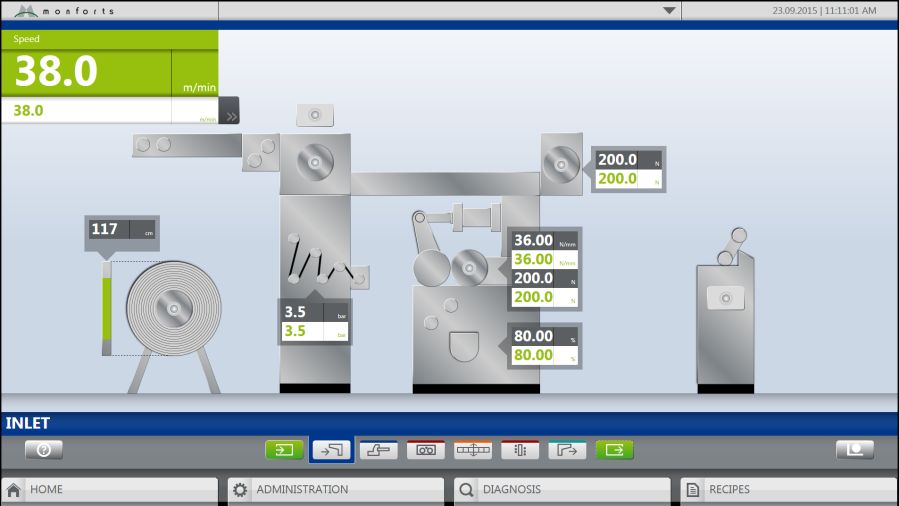

New ‘smartphone’ features for Montex 8500 New and further enhanced visualisation software with ‘finger tip’ control features offering smart phone-type techniques for Monforts machine operators and ensuring smarter operating procedures. Available for Montex 8500 stenters, the new model also features a redesigned operator’s platform with ergonomic advantages during finishing and coating processes.

High Performance Denim Ranges A new Denim stretching unit will also be presented for achieving smooth stretching under the highest processing speeds during denim shrinking and finishing being incorporated into well proven twin shrinking units with twin felt calender.

The Eco-Applicator liquor application process offers significant energy savings with reduced drying capacity required for a wide range of applications such as felt finishes, coated materials and medical textiles including Nano coating, water repellancy, softeners, flame retardency and insect repellancy.

A new version for knitted fabrics will be presented at ITM.

It has been designed to apply a liquor to one side of the fabric; to apply a liquor to both sides of the fabric; to apply different liquors to either side of the fabric; or to apply two different liquors consecutively to a single side of the fabric.

Pic: Monforts Eco-Applicator Complete range of coating solutions from Monforts Single sourced solutions ranging from single sided applications of finishing agents such as, for example, outdoor clothing and functionalization of textiles in the home textiles sector, through to sophisticated lightweight construction using innovative textile-based coated materials in the automotive and aerospace industries are now available.