#Yarn & Fiber

Manmade fibers continue to conquer new areas of application

Manmade fibers continue to grow in popularity: 52.7 million tons of these fibers were produced around the world in 2011, according to the industrial association Industrievereinigung Chemiefaser IVC. As a result, manmade fibers made up 65 percent of global fiber production. In contrast to natural fibers like cotton that compete for land with, among other things, food corps, the organic materials used in the manufacture of manmade fibers are available in almost limitless quantities and are extremely low cost. Another benefit of Manmade fibers is their high degree of flexibility. Manmade fibers can be tailored to meet a wide range of needs by modifying the raw materials and production processes or by applying various finishing treatments to give them specific characteristics. For example, fibers can be designed to resist soiling, provide exceptional thermal insulation while retaining breathability – whether they are made to be thinner than silk or thicker than wool.

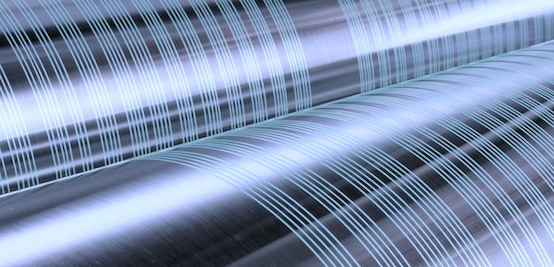

Functional clothing for work and play These qualities make Manmade fibers particularly attractive for the production of clothing: The market research firm Euromonitor reports that 54 % of global fiber production flowed into the clothing industry in 2011. Manmade fibers are used to produce functional athletic clothing, underwear, tights, breathable summer clothing and work clothing that protects against heat, cold or dampness. Another reason for the success of manmade fibers in the clothing industry is that they now feel much like natural fibers and are comfortable to wear, which is achieved by special finishing processes like texturing. Here, the surface of the fibers is modified, creating the feel of natural fibers.

Non-soiling home textiles and carpeting At 25 % of Manmade fiber production, home textiles are another large market. Typical products include tablecloths, napkins, curtains and carpeting. Until the second half of the 20th century, carpets were almost exclusively made of natural fibers. Today, about 88 % of carpeting is made of manmade fibers. There are many reasons why manmade fibers have become the fiber of choice in this area: they cost less to produce, are more robust, easier to maintain and hypoallergenic.

Up to 20 kilograms of manmade fibers in every car Manmade fiber applications are by no means limited to clothing and home textiles; they help make today’s vehicles safer and more comfortable. Cars now have up to 20 kilograms of textile products that generally consist of manmade fibers. One example is tear-resistant fibers made of polyamide, polyester or nylon that are used in seat belts and airbags. Flat textile fabrics – so-called nonwovens – are used for roof linings, floor coverings, the interior lining of trunks and doors, seat covers, upholstery and insulating matting in the engine compartment. Tire cords are another area where manmade fibers are used in vehicles. These cords are made of special polyester yarns that are exceptionally tear-resistant but remain elastic while providing extremely high temperature and form stability. The cord is a surface made of such yarns and is processed with the tire rubber at a temperature of 200 degrees. It is situated amid several layers of rubber and provides stability to the complete tire on the road.

High-tech membranes facilitate unique structures There is a tremendous growth potential for so-called technical textiles, which today only account for 12% of global fiber production. Today’s primary areas of use are in the construction, medical and packaging industries. Growing by an estimated 5% to 8% per year, the market for construction textiles area shows exceptional potential. So-called textile membranes have made it possible to create incredible facilities such as the international airport in Bangkok and the stadiums that hosted the UEFA Euro 2012 soccer championships in Warsaw and Kiev. The material used in these structures is specially-coated polyester or fiberglass that provide protection against heat, fire and even soiling.

Geotextiles stabilize roads, dams and walls Another important application is geotextiles. The Freedonia Group predicts this segment will generate annual growth rates in excess of 8 %. By 2015, global demand for geotextiles is expected to reach a total that would cover an area of 4.5 billion square meters if rolled out. Geotextiles are used in road construction to provide stability to the subgrade, to act as a filter and drainage elements and to reinforce asphalt. In addition, they serve as a separating layer between sand and gravel and as a means of strengthening dams and walls. They are made of particularly tear-resistant manmade fibers, which can be processed into water-permeable plastic mesh covers.

Fiber-reinforced concrete is more corrosion resistant One of the more promising textile materials being used in the construction industry are carbon fibers. Uses for these light, extremely stable fibers are not limited to aircraft and sports cars: they are also a replacement for the steel used to reinforce concrete. This results in reduced corrosion and improved fire protection. Because the reinforcement provided by textiles with two- or three-dimensional fiberglass or carbon fibers is much thinner than steel, architects have much greater freedom when designing structures. One single layer of carbon fiber in concrete increases concrete’s load-bearing capacity fourfold.

Nonwoven fabrics are optimal for roof coverings Heat retention, energy efficiency and soundproofing are key issues in the construction industry and the reason nonwoven fabrics are becoming increasingly popular. Textile fabrics demonstrate their unique strengths in this area of application. In thin layers, they prevent undercooling and absorb very little dampness. They are particularly suitable for roof construction as they provide more sealing flexibility than such materials as foam, glass and mineral wool. So-called spunbond nonwovens made of satin-finished polypropylene are placed between the roofing material and the substructure to insulate and prevent seepage while being permeable to air and resistant to mold and mildew.

Pic: Wirh 420.000 tons roofing has the lion share in the Segment of technical nonwovens

Roofing Underlayment

- Polymer: PP

- Basis weight: 50 – 120 g/m²

- Filament size: 4 – 7 dtex

- Throughput (for example:Oerlikon): up to 240 kg/(h*m)

- Standard product width (for example:Oerlikon): 1500 mm

- Machine standard width (trimmed) (for example:Oerlikon): 3200 mm for up to 6,000 tons per year (other widths available)

- For use between roofing tiles, wooden Roof

Market and technology leader

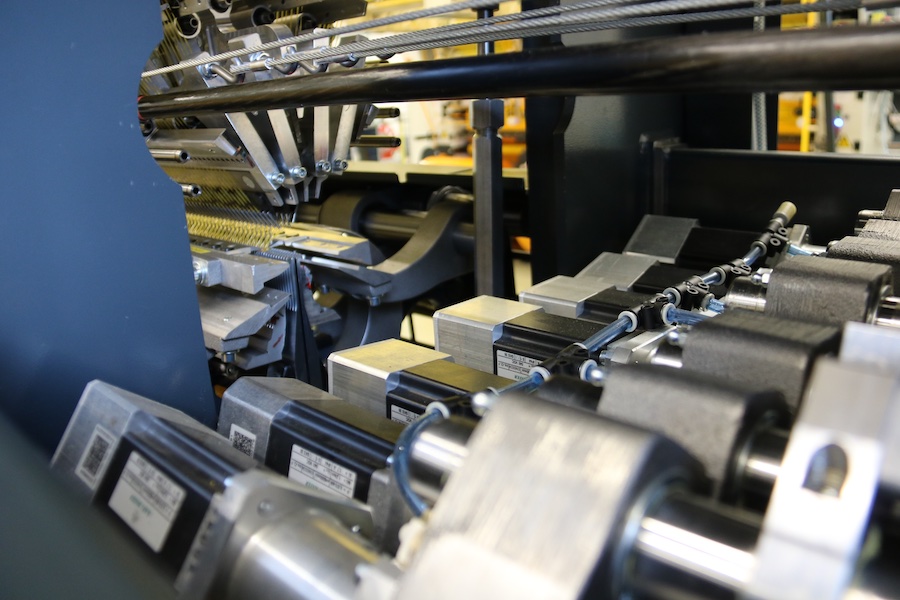

Market and technology leader with a broad product range for machines and systems used in manmade fiber production, refinement and processing is the Swiss Oerlikon. With its brands Oerlikon Barmag and Oerlikon Neumag, Oerlikon is exceptionally well positioned in this market segment to benefit from the strong growth generated by manmade fibers and technical textiles. The product range includes turnkey production solutions extending from granulate to finished products. Oerlikon Barmag has been a leader in spinning systems for manmade fibers since 1922. With its innovative machine solutions, Oerlikon Neumag covers the entire production range for geotextiles and spunbond nonwovens. In addition, Oerlikon Neumag is the world’s leading provider of carpet-yarn production machinery with a market share of more than 80 %.