#Yarn & Fiber

Lenzing on track for recovery after anticipated difficult start to the financial year

Textile fibers recorded moderate but steadily improving demand. Business with fibers for nonwovens and with dissolving wood pulp performed better than expected. Raw material and energy costs were still at an elevated albeit decreasing level.

- Revenue grows to EUR 623.1 mn – fiber sales recovered over the course of the quarter

- EBITDA and net result for the period down compared with the first quarter of 2022

- Cost reduction program of more than EUR 70 mn being implemented according to plan

- Production of TENCEL™ brand modal fibers successfully launched in China

- Lenzing confirms guidance for 2023

Revenues increased by 1.3 percent compared to the prior-year quarter to EUR 623.1 mn. This growth was primarily due to higher pulp revenues, while fiber revenues were down. As a consequence, earnings before interest, tax, depreciation and amortization (EBITDA) decreased by 66.2 percent year-on-year to EUR 29.7 mn in the first quarter of 2023. The net result for the reporting period amounted to minus EUR 64.9 mn (compared with EUR 34.1 mn in the first quarter of 2022) and earnings per share amounted to minus EUR 3.03 (compared with EUR 0.87 in the first quarter of 2022).

Lenzing launched a reorganization and cost-cutting program in the third quarter of 2022 and is fully on track with its implementation. More than EUR 70 mn in annual cost savings are targeted once the program has been fully implemented. Moreover, further measures were launched to bolster free cash flow. This amounted to minus EUR 132.3 mn in the first quarter of 2023 (compared with minus EUR 102.9 mn in the first quarter of 2022), particularly due to the negative result and the completion of strategic investment projects. In addition to the cost-cutting program, further steps to reduce working capital are currently being implemented and currency and energy price hedging are being reorganized. All measures are being implemented against the background of a solid liquidity reserve of EUR 639.5 mn.

“After the crisis year of 2022, the negative after-effects were still clearly evident in the first quarter of 2023. However, we noted signs of recovery in terms of demand as well as energy and raw material costs during the quarter. Lenzing has successfully made great efforts in relation to both costs and liquidity and is well prepared for an upturn in demand,” notes Stephan Sielaff, Lenzing Group CEO. “In the medium and long term, we continue to anticipate a strong growth in demand for Lenzing’s sustainable products. We are convinced that our two investment projects in China and Indonesia will further strengthen our positioning in this respect.”

Focus on sustainable specialty fibers

In addition to the continued implementation of the reorganization and cost-cutting program, the implementation of the “Better Growth” corporate strategy was also advanced in the first quarter of 2023. The corporate strategy aims to better serve the structurally strong growth in demand for biodegradable and responsibly produced specialty fibers under the TENCEL™, LENZING™ ECOVERO™ and VEOCEL™ brands. In accordance with the strategy and following the successful implementation of the two key projects in Thailand and Brazil, Lenzing will continue on its profitable growth trajectory, sharpen its focus on sustainable and high-quality premium textile fibers and nonwoven fibers, and in parallel further advance the transition from a linear to a circular economy model.

Since 2021, Lenzing has invested more than EUR 200 mn in production sites in China and in Indonesia in order to convert existing capacities for generic viscose into capacities for environmentally responsible specialty fibers.

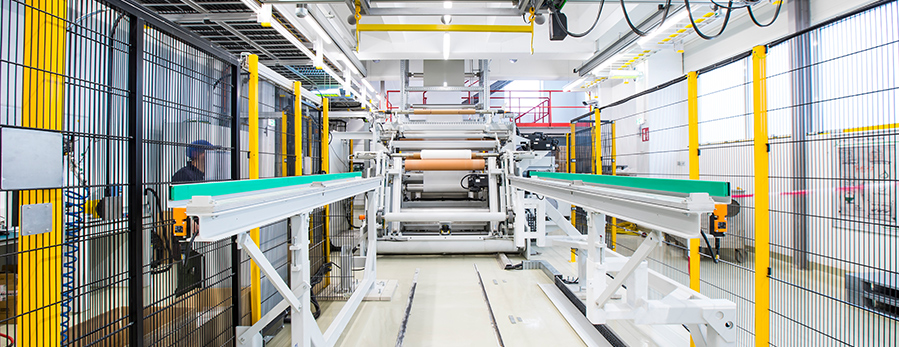

In Nanjing (China), the conversion of a production line to TENCEL™ brand modal fibers for textiles and apparel was successfully completed in the first quarter of 2023. For the first time, Lenzing can thereby also offer locally produced TENCEL™ fibers to its Chinese customers and consequently serve structurally growing demand on an even better basis. Due the conversion of the line with a nameplate capacity of 35,000 tonnes per year, the fiber portfolio of the production site now consists exclusively of environmentally responsible specialty fibers. Moreover, Lenzing is continuing to work consistently on the gradual conversion of the Chinese site to green energy in order to further reduce carbon emissions.

As part of the investments at the site in Purwakarta (Indonesia), Lenzing is creating additional capacity for LENZING™ ECOVERO™ fibers. Lenzing is investing locally in reducing carbon emissions as well as air and water emissions. The conversion work is proceeding according to plan, and the site will be converted into a pure specialty viscose supplier prospectively before the end of the year.

Changes on the Managing Board

Lenzing also recently announced personnel changes on its Managing Board. Robert van de Kerkhof, Chief Commercial Officer Fiber and a Managing Board member since 2014, informed the Supervisory Board that he would not be available for a further extension of his contract, which runs until December 31, 2023. He will continue to drive forward the sustainability area, including the Carbon Roadmap, as Chief Sustainability Officer until the end of his current term of office. CEO Stephan Sielaff will essentially assume responsibility for sales in the Fibers Division. The Lenzing Managing Board will thereby be reduced from four to three members as of January 1, 2024.

Outlook

The war in Ukraine and the more restrictive monetary policy pursued by many central banks in order to combat inflation are expected to continue to influence global economic activity. The IMF warns that risks remain elevated overall and forecasts growth of 2.8 and 3 percent for 2023 and 2024 respectively. The currency environment is expected to remain volatile in the regions relevant to Lenzing.

This market environment continues to weigh on the consumer climate and on sentiment in the industries relevant to Lenzing. However, the outlook has brightened somewhat recently.

Demand picked up tangibly after the Chinese New Year. As a consequence, capacity utilization improved and stocks were further reduced both at viscose producers and at downstream stages of the value chain.

In the trend-setting market for cotton, signs are emerging of a further buildup of stocks in the current 2022/23 crop season. Initial forecasts for 2023/24 anticipate a more balanced relationship between supply and demand.

However, despite signs of recovery in both demand and raw material and energy costs, earnings visibility remains limited overall.

Lenzing is fully on track with the implementation of the reorganization and cost reduction program. These and other measures are aimed at positioning Lenzing in the best possible way for the expected market recovery.

Structurally, Lenzing continues to anticipate growth in demand for environmentally responsible fibers for the textile and clothing industry as well as for the hygiene and medical sectors. As a consequence, Lenzing is very well positioned with its “Better Growth” strategy and plans to continue driving growth with specialty fibers as well as its sustainability goals, including the transformation from a linear to a circular economy model.

The successful implementation of the key projects in Thailand and Brazil as well as the investment projects in China and Indonesia will further strengthen Lenzing’s positioning in this respect.

Taking into account the aforementioned factors and assuming a further market recovery in the current financial year, the Lenzing Group continues to expect EBITDA in a range between EUR 320 mn and EUR 420 mn for 2023.