#Recycling / Circular Economy

Teijin Frontier’s new high-stretch SOLOTEX®ECO-hybrid fiber made with plant-derivedand recycled materials

SOLOTEX®ECO-Hybrid represents a new line in Teijin Frontier’s polytrimethylene terephthalate (PTT) fiber SOLOTEX®family. SOLOTEX®ECO-Hybrid filament yarn and textile will be introduced as a featured product for 2020 autumn/winter fashion apparel, offering many possibilities for enhanced sportwear, uniforms and more. Annual sales of SOLOTEX®ECO-Hybridare expected to grow from JPY 500 million in 2020 to JPY 1.5 billion in 2022 (filament yarn equivalent).

Key Features of SOLOTEX®ECO-Hybrid

Polymers

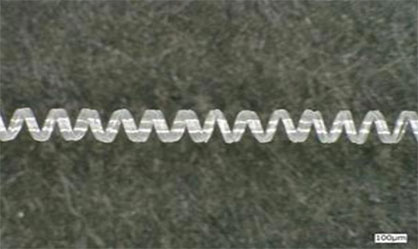

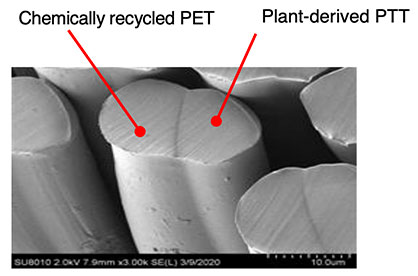

Extra stretchability achieved with newtechnology for conjugating PTTpolymer and polyethylene terephthalate (PET) polymer made with chemically recycled raw material, which are then processed to create a crimp structure.

Filament production

Crimp structure is equivalent to that of petroleum-derived raw materials.Dyeability achieved with optimizedyarn-making conditions.

SOLOTEX®ECO-Hybrid has the same features asconventional S/S conjugated fibermade with petroleum-derived raw materials.

Eco-friendly

PTT polymer is partly made with plant-derived raw materials and PET polymer is made with chemical recycled raw materials such as used polyester fibers.

Versatile fineness

Wide range of fineness, from 33-330 decitex, *and filament yarn processing is possible.

Highly practical

Very stretchable and dyeable, equivalent to those of petroleum-derived materials, and soft texture.

*Thread thickness measured in grams per 10,000m

In recent years, demands have been growing for materials offering functionality and comfort, such as stretch ability and soft textures. Also, users are seeking eco-friendly fabrics made with recycled and plant-derived materials.

Teijin Frontier’s existing S/S conjugated fiber comprises a highly stretchable SOLOTEX®PTT-fiber polymer made with about 40% plant-based raw materials and PET made of recycled raw materials. The newest version, SOLOTEX®ECO-Hybrid, solvesthe problem of achieving a consistent crimp structure in an eco-friendly S/S conjugated fibermade with recycled PET.