#Weaving

Weavers in pole position

2FAST accelerates performance with speed, quality and versatility

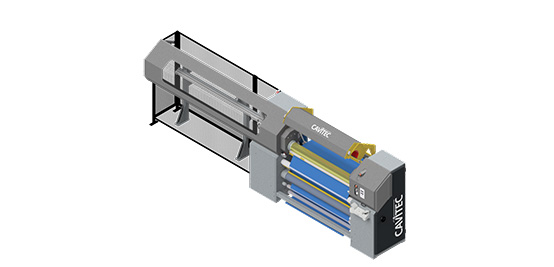

The FAST name stands for Flexible Advanced Shuttleless Technology – and 2FAST is the pride of SMIT. The company’s expertise dates back to 1938, focused on developing best structural concepts across the whole machine. Today, that takes in mechanical, electronic and communication aspects, creating optimum weaving machine configurations for high-quality fabrics in the widest application range.

True to the racing spirit…

Imagine an F1 car at the start of a race, or a motorcycle which zooms to 100 km/h in less than three seconds... That’s where 2FAST ranks in the weaving machine category. It shows highest starting acceleration and 100% beat-up efficiency, right from the first weft insertion. Maximum torque is also available for extremely heavy shedding requirements, guaranteeing optimal acceleration to top speeds, along with minimum vibration.

That explains why the SMIT ’racing machine’ delights weavers producing apparel, home textiles, technical applications and fabrics with exclusive yarns and patterns. All applications benefit from minimum weft cutting, transfer and release speeds. The spherical crankshaft and one gear stage for the rapier drive maintain highest regularity in weft insertion.

From apparel to home textiles and more

The SMIT modularity concept brings utmost versatility, along with performance and quality. Options range from apparel and denim weaving to home textile applications – and the brand-new leno-force system can be quickly adapted to the most varied fabric types. Weavers can program the false selvedge and leno yarn crossing, pick-by pick, for each side independently. This maximizes efficacy in controlling weft stretching and weft tail reduction – and all at the highest operating speeds.

The patented new gripper design suits all yarn and fabric types, providing a reduced cross-section and optimized warp shed geometry. 2FAST can also handle fancy articles, requiring a wide range of weft types and counts, with the high speed and precision. The latest software-controlled E-CUT/AWC ensures optimal cutting conditions.

“Software-based control and automation, smart algorithms and data analysis – it’s all embodied in this rapier loom, which is ready for industry 4.0,” says Giuseppe Castelli, CTO at SMIT.

Quality security is afforded by special back-rest control system. Warp tension stability is ensured by a new layout of the load cell; so that any resonance effect – even at highest performance rates – is avoided by the back-rest elastic recall system. Uniform tension from full to empty beam is guaranteed by the standard warp deviation roller. These new features deliver production volume and value for weaver.

Green performance

SMIT engineers prioritize ambitious energy-saving goals, with comprehensive know-how covering all critical processes. For example, they sought to eliminate auxiliary cooling systems, developing a high-efficiency brushless motor with permanent magnets, for lowest heat generation with highest power. A further sustainability benefit came with the new short mechanical transmission for highest regularity while guaranteeing lowest energy consumption – also used in combination with Jacquard systems.

Green performance means energy reduction as well as waste reduction. 2SAVE is the SMIT green feature, controlling weft thread tension outside the fabric edges. 2SAVE cuts false selvedges, saving fabric waste during production. It’s also a most effective system for weft yarn saving (left and right side), another sustainable value-added feature.

The SMIT R&D team leave no detail untouched when investigating technical solutions to be tested and proven. That’s why 2FAST earned the ACIMIT Green Label for machines developed with the methodology of ‘Product Design for the Environment’, from the Italian textile machinery association.

“We are very proud of all advantages embodied in the compact design of the new 2FAST and we are glad to speak it out loud – while also using advanced technology to make the machine itself even quieter,” says Castelli.