#Weaving

Weavers of carbon fabrics

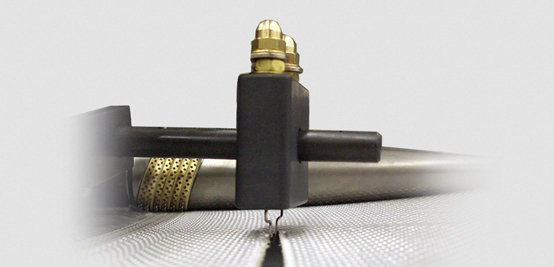

RELY ON WEFTMASTER FALCON-I

In the case of inlay-components with a carbon look, even the smallest irregularities are a problem. Hence, carbon fabrics must have controlled quality to avoid sporadic defects. Weavers of carbon fabrics who are working closely together with car manufacturers don’t take any risks - they rely on Loepfe's FALCON-i to keep fluff or filamentation out of their top quality fabrics.

By using the unique detection features of Loepfe's FALCON-i yarn sensor to remove fluff or filamentation from the weft-yarn, waste is dramatically reduced in the carbon fabric production process. A simple calculation reveals that there’s a quick return on investment for the weaver.

The applications where FALCON-i can improve product quality are not limited to those mentioned here. Coated technical fabrics such as tarpaulins or sailcloth can only be perfect when using FALCON-i for weaving the base material, in order to avoid fish-eye defects.

Weavers with a focus on high quality technical textiles benefit from using the unique detection capabilities of FALCON-i to improve the quality of their products while avoiding customer claims or expensive patching.

FALCON-i offers selectable sensitivity levels to cope with many different applications. Since the sensor is optical, the nature or conductivity of the yarn processed is of minor importance. Smooth yarn guidance allows for very selective fault sensitivitysettings.

This specialized yarn sensor product from Loepfe Switzerland is in high demand for the production of technical textile fabrics that find their application in automotive, medical, aeronautics, filtration, recreational sports, renewable energy - and many other industries too.

Learn more about features and applications of FALCON-i here or contact one of our experts at service@loepfe.com