#Textiles & Apparel / Garment

LEONHARD KURZ presents spectacular embellishment solutions at Première Vision

Under the motto ‘Let Fashion Shine!’, the company will be presenting certified solutions for extraordinary textile decorations that ensure shiny appearances in the fashion world.

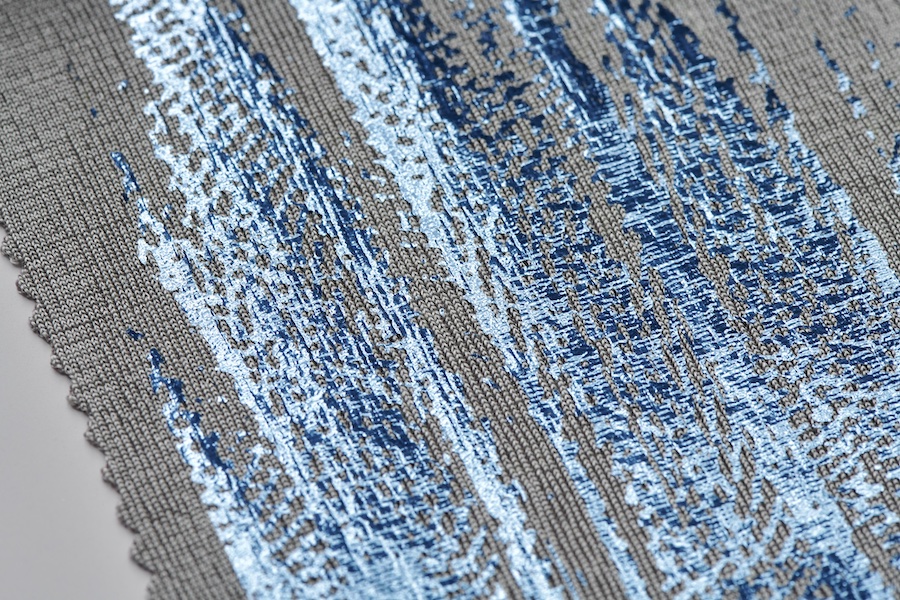

LUXOR®/ALUFIN® TX-A and LUXOR®/ALUFIN® TX-A ST: Spectacular look, semi-transparent highlights

For Première Vision, KURZ once again has high-quality solutions for eyecatching fashion looks in its portfolio: LUXOR®/ALUFIN® TX-A combines a premium look with reliable processing and impresses with its high gloss, as well as a particularly uniform appearance. In addition, the semi-transparent LUXOR®/ALUFIN® TX-A ST finish opens up exciting perspectives and completely new dimensions of surface finishing.

Both solutions are characterized by brilliant gloss, improved washability and high abrasion resistance and are also suitable for both full-surface and partial decoration. LUXOR®/ALUFIN® TX-A and LUXOR®/ALUFIN® TX-A ST can even be processed on natural and synthetic materials such as woven or knitted fabrics and lace, as well as on artificial and genuine leather, and are suitable for chemical cleaning. With this portfolio, KURZ gives designers scope for unique creations based on state-of-the-art technology. "For many, hot stamping in the textile sector is synonymous with large-surface, chunky prints. But this technology is so versatile. It is precisely this wealth of facets that we want to clearly demonstrate with our trade fair presence," explains Nicola Bauer, International Product Manager Textiles at LEONHARD KURZ.

Safe and responsible through OEKO-TEX® certification

As part of the process chain in the textile industry, KURZ is aware of its responsibility to people and the environment. With LUXOR®/ALUFIN® TX-A and LUXOR®/ALUFIN® TX-A ST, the company contributes to sustainable and safe textile decoration. This extends the life cycle of garments and preserves their attractiveness. Like all KURZ finishing solutions, the two innovative finishes are developed according to the strictest quality standards and are free of harmful substances. They are certified according to OEKO-TEX® STANDARD 100 and classified as especially safe and health-friendly in the highest product class 1. "For us at KURZ, it goes without saying that we take responsibility by contributing to a long textile life cycle and thus conserving resources. We make this especially transparent with the OEKO-TEX® certification of our products in the LUXOR®/ALUFIN® product family and LUMAFIN® Clear. This means that our customers benefit from our innovative solutions and also have the certainty that all environmental standards are met," says Nicola Bauer.

At a glance

+ Première Vision from February 11 to 13, 2025 in Paris

+ LEONHARD KURZ Stiftung & Co. KG: Hall 5A 66

+ Category: Accessories, Focus: Embellishment

+ Product groups: Premium textile decoration, textile finishing, hot stamping finishing, functional textiles, transfer technology