#Textile chemistry

Renewable Carbon Initiative (RCI), CO2 Value Europe (CVE) and nova-Institute publish a study showing the CO2 reduction potential of the chemical industry through CCU

CO2 Reduction Potential of the Chemical Industry through Carbon Capture and Utilisation (CCU)

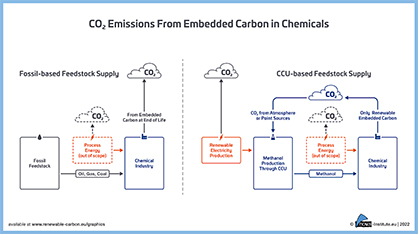

In an exploratory scenario, the study “CO2 reduction potential of the chemical industry through CCU” investigates the greenhouse gas (GHG) reductions that can be achieved in the global chemical and derived material industries if the entire demand for embedded carbon is met solely and exclusively via CO2 instead of from fossil sources. Major simplifications are used to achieve transparency and comprehensibility of the issue. Methanol (CH3OH) is considered to cover the needs for hydrocarbons for chemicals and derived materials among the various chemical intermediates as a representative pathway for renewable carbon. It is a plausible scenario to assign methanol a central role in supplying the chemical industry of the future.

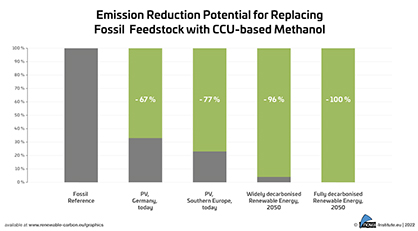

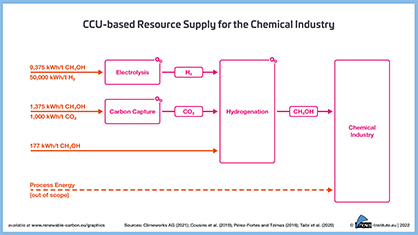

The examined CCU-based production route includes CO2 capture as a mix of direct air capture (DAC) and capture from different point sources, hydrogen supply and the hydrogenation reaction for methanol synthesis. The GHG emissions related to CCU-based methanol synthesis depend on the emissions of the renewable energy production. Emissions of CCU-based methanol could be 67 to 77% lower compared to emissions from releasing embedded carbon of fossil fuels, when using current energy supply based on photovoltaics. With improvements in renewable energy production, the reduction could increase to levels between 96 and 100%.

The annual global demand for carbon embedded in chemicals and derived materials could rise from 450 million tonnes of carbon (Mt C) today to 1,000 Mt C by 2050. Meeting this demand with CCU-based methanol would cause an immense demand of 29.1 PWh/year of renewable energy. Enormous efforts would have to be made to deploy sufficient renewable energy. If desert photovoltaic is used to produce the hydrogen, theoretically 1.3% of the Sahara area would be required to cover the entire demand.

Yet, with fully decarbonised energy supply, an amount of 3.7 Gt CO2/year can be saved. These GHG emission savings are significant – even in comparison to today’s global emissions of 55.6 Gt CO2 eq/year. The result shows that CCU is a promising technology to reduce GHG emissions related to embedded carbon supply – if sufficient renewable energy is available. CCU-based carbon will be an important pillar of a future build on renewable carbon, complementing carbon from recycling and from biomass. To allow CCU to contribute to a climate-friendly supply of feedstock for the chemical industry global PV and wind capacities must be rapidly expanded.

The study “CO2 reduction potential of the chemical industry through CCU” is available for free at http://www.renewable-carbon-initiative.com/media/library