#Texprocess 2022

PFAFF & KSL at Texprocess in Frankfurt

The material thickness detection and real-time adjustment (360° monitoring) feature ensures optimum stitch formation, even when sewing over cross-seams and interlinings. By using the roller presser (running close to the needle), the material can be worked in with pinpoint accuracy. Optimal work with a clear view of the sewing material is assured. The PFAFF 3834 guarantees smooth seams and even stitch formation, especially when sewing sensitive and difficult fabrics.

Electronic shoe post-bed machine with short-thread trimmer and thread tension regulation

The new PFAFF 1591 is also equipped with thread tension regulation, which automatically adjusts the thread tension to the material thickness being handled. Material thickness detection and adjustment in real time (360° monitoring). Additionally, the machine has a short-thread cutter and a “neat seam start”, which makes the thread nest of the upper thread disappear.

Absolutely straight stitch position with two-needle seams

The new PFAFF 5696 comes as standard with a narrow 25 mm column. The machine is an expansion of PFAFF INDUSTRIAL’s “chain stitch inline” construction kit - it is offered to the customer with a standard and a long-arm version (700 mm clearance). The machine is used for two-needle decorative seams on large, bulky and voluminous parts (dashboards, consoles, leather, technical applications etc.). The mirrored hooks of the PFAFF 5696 is an absolute innovation, ensuring a straight stitch position of the parallel seams with no saw-tooth look. The machine is great value for money.

Upgrade of the PFAFF 3686 and 3688 automatic sewing machines

The new PFAFF 3686 is an upgrade of the PFAFF 3586 short seam automatic sewing unit and comes equipped with DAC-Compact control. In Frankfurt, PFAFF INDUSTRIAL will be showing the 3686-25/11 – a version with up to 490 mm seam length, for two-pointed darts. Thanks to the short-thread trimmer with a thread end < 5 mm and the “Neat seam start” device, this solution is also used by high-quality shirt and blouse manufacturers. The new PFAFF 3688 pocket-setter builds on the successful and flexible concept of the 3588 and expands its range of applications. The new PFAFF 3688 features a simplified, intuitive operating concept plus electronically controlled thread tension, direct drive, carriage feed with servo drives, network connection (PFAFF CONNECT) and adjustable vacuum strength. The fullness function and the automatic bartack reinforcement, which enables high-quality processing of delicate stretch fabric, are other new features.

PFAFF CONNECT

With PFAFF CONNECT, PFAFF INDUSTRIAL will be exhibiting for the first time ever a network connection for sewing and welding machines. Thanks to the VNC server, integrated into the control panel, all machine functions can be viewed and changed at any time via a network. Using the “BoxPc” option, all machine and production data can be read out and displayed on a dedicated website assigned to the machine.

Seam sealing: The final step to complete process control

Until now our latest PFAFF 8303i has been the “state of the art” seam taping machine. It is still unique in controlling the basic process parameters, such as air flow, pressure, temperature and speed. Now PFAFF has added the last missing link for unique process control, the 3-D axis nozzle position. The PFAFF 8333 is the first machine in the world, that really allows all relevant determining factors to be preset to certain welding programs. The changeover from one application to another can be done by just pressing a button. No tools, no guessing, no uncertainties. And no experienced operators or technicians needed. Just plug and play.

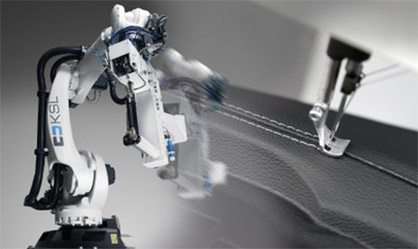

Robot-assisted manufacturing with KSLengineering

With the KL 500 robotic unit KSL is presenting a complete 3D sewing cell, as used in production plants for the manufacture of vehicle dashboards all over the world. Using this unit, entire dashboards are stitched with high efficiency, process reliability and repeatability. The unit includes robot, a Vision system, component holders, rotary indexing table, sewing heads (2-needle double chain stitch - special post), protective fence concept etc. Using the KL 500, various products can be manufactured with minimal conversion effort. The only things that need to be changed are the component holders and possibly the sewing head. Thus, the unit combines flexibility with the highest level of precision and productivity.

KSL CNC technology with new technical refinements

The new KSL 352 is a solution for sophisticated safety, functional and decorative seams. The sewing head with horizontal hook, which is tailored to the machine, enables the option of a bobbin changing system. Many new technical refinements have been implemented in the KL 352, such as: Thread tension and foot height can be individually set for each seam section. These technical innovations increase process reliability and ensure a high-performance in the multidirectional sewing process.

Highest process reliability + maximum performance. This is what the CNC sewing unit KL 110 with rotating head for servo-controlled continuous or intermittent free programmable sewing of head-airbags stands for. The rotating head ensures highest efficiency and quality for tangential multidirectional sewing operations. The KL 110 is presented VISION SYSTEM - this intelligent system compensates for tolerances which have been developed. These arise due to the shrinking of materials and tolerances, including during the punching of perforations. Specifically, the Vision system compares an image of a master example with the image of the piece mounted in the sewing template. By means of individual measurement points, the entire seam pattern is automatically corrected within the sewing program. Process reliability is significantly increased, waste is reduced. The automatic template changer system ensures a full-overlapped workflow.