Becoming digital, step-by-step – these days many apparel industry companies are going down that route with their product development. At the Texprocess, the Human Solutions Group will showcase product development, production and showroom solutions – and several rooms are solely dedicated to the various process steps.

It’s no longer a pipe dream – digital is now!

“At the Texprocess, we’ll be showing our guests just what digitization can do for them – and that it’s no longer a pipe dream. Digital is now – we have developed our solutions for the Texprocess to such an extent that the entire product development process chain is now digitally possible,” says Dr. Andreas Seidl, CEO of Human Solutions. “In our booth rooms, visitors will experience how our solutions can be integrated into a perfect interactive process and how they can reduce their time to market significantly.”

Three rooms in the booth bundle the different process steps into different topics:

Digital Design Room: Sample-free all the way to production In the Digital Design Room, you’ll see how the ideal prototype can be completely designed, tested and approved – digitally. This is the room in which the entire process for creating a new collection is staged. It starts with the collection of ideas on the Digital Fashion Board, the successor to the analog Mood-board. Sketches, images and existing designs can be compiled here – and data from the PLM system is connected directly and always available. The story continues with the defining of the target group in iSize, the international body dimensions portal. Then it’s time for the next step in this digital product development, during which all the necessary decisions for the collection are made and price ranges, materials and the required accessoires are determined in the PLM system. A pattern is then developed in Cad.Assyst and simulated and visualized in Vidya – naturally in 3D. The result is a pattern file with which you can start your production.

Digital Production Room – Batch sizes now take a back seat Customers are always on the lookout for more individual offers – and Human Solutions will show you how to create the production technology prerequisites for these offers in the Digital Production Room. The entire production process can be seen in this room, from compilation of the order data and its optimization to nesting and cutting – and innovative ideas and diversity play the main roles here, relegating batch sizes to the back seat. Human Solutions will also demonstrate that the sector profiting greatly from this individualization process is Corporate Fashion and that it’s not only individual single pieces that benefit. The VITUSbodyscan body scanner is also installed in the Digital Production Room. Visitors can have themselves accurately measured and a realistic, color image of the scanned person is created in just a few seconds.

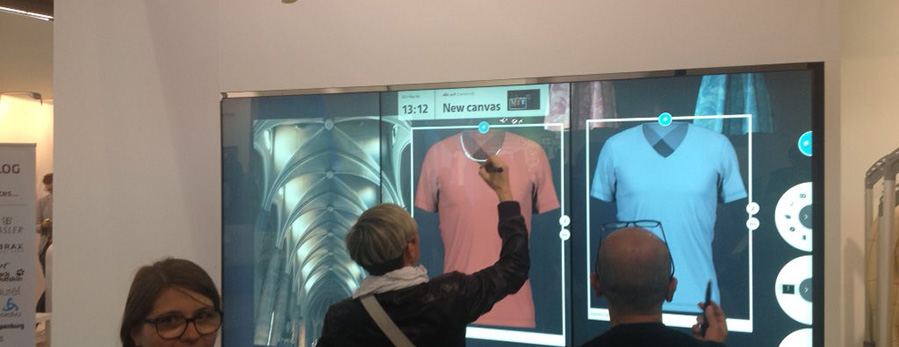

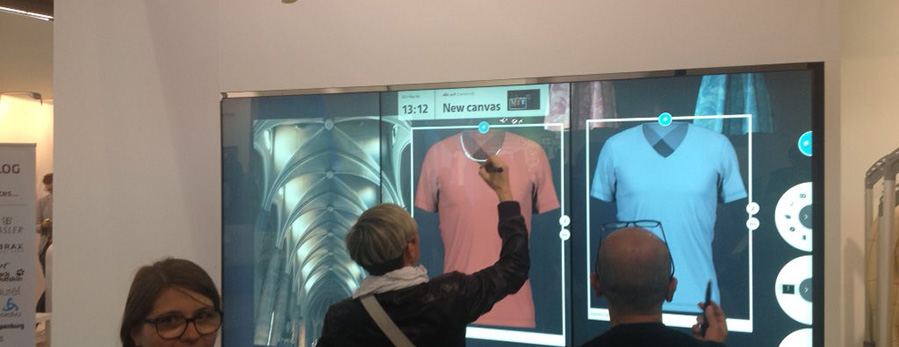

The Digital Show Room – provide more diversity digitally In the Digital Show Room, several product variants and sizes are available and all other information is also digitally available. This scenario is played out with real clothing. The garments are equipped with a QR code that visitors can hold up to the Digital Fashionboard. A Webshop with the selected product then opens on the board, also displaying variants of the garment in different colors and patterns. The Virtual Mirror enables the on-the-spot determination of the right size and the virtual try-on; the Bodyprofiler and Vidya perform these functions in the Web-shop. An avatar of the exhibition visitor then tries on the garment virtually. The collection can also be staged on the Digital Fashionboard, for example, by showcasing a fashion show, matching accessoires and providing atmospheric music. One particular highlight in the Digital Showroom is the Virtual Reality Room, where visitors can see how digitization virtually brings partners in different locations together. In this room, ‘Digital is now’ means ‘put on your virtual reality glasses and coordinate a fully-networked, 360-degree collection with partners all over the world.’

In Hall 6 – the Digital Textile Micro Factory How to design a customized garment and produce it within a short timeframe is showcased in the Digital Textile Micro Factory in Hall 6. In the Microfactory, presented for the first time at the Texprocess, you’ll see the completely-integrated production chain for textiles right before your eyes – from design and digital printing to automatic cutting and ready-made apparel, and the Human Solutions subsidiary Assyst will use the 3D simulation software Vidya to demonstrate how a garment is created digitally. The Digital Textile Micro Factory is a joint project with the DITF Denkendorf and other partner companies.

Vidya Dress, (c)2017 Human Solutions