#Techtextil 2022

Stäubli at Techtextil / Texprocess Frankfurt 2022

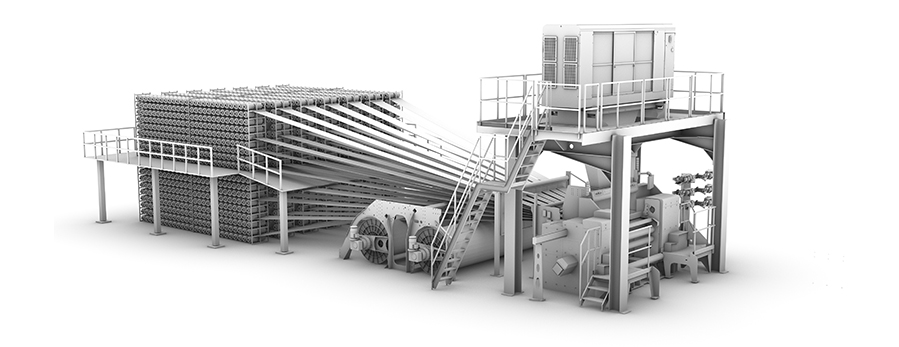

Stäubli’s reputation for quality machinery is based on ingenious technologies developed through continual R&D, the use of top-quality materials, and comprehensive service before, during, and after the machinery installation. Stäubli textile machinery is in daily operation around the world, producing all sorts of technical fabrics, including the most demanding. Producing technical fabrics such as one-piece woven (OPW) airbags, custom fabrics for lightweight construction, and artificial grass is subject to highest demands, and these are fully met by the company’s broad range of cam motions, rotary dobbies and Jacquard machines, but also its complete TF weaving systems. In addition, Stäubli provides renowned automation solutions to optimize time consuming weaving preparation processes, such warp tying and drawing-in.

Visitors to the Stäubli booth will see the MAGMA tying machine, which is ideal for processing technical yarns, including PP tape.

Stäubli – Competence in technical weaving and supporting research

A Stäubli TF20 weaving system was recently installed at the Hof University of Applied Sciences, more precisely its Institute for Material Sciences, in Germany. The purpose of this installation is to support the study of new material mixes, especially with carbon and/or ceramics, and new applications for various industries. Here, renowned researchers and their students pursue their daily quest for new materials, studying their behavior in various production processes, including weaving. The institute works with the renowned Fraunhofer Institute, allowing the opportunity to conduct research on ceramic fiber production and processing fabrics.

In such manufacturing processes, every step is crucial and must be executed using specifically adapted machinery operating with the utmost precision. The TF weaving system comes with a shedding solution that offers unlimited binding options and is encapsulated in order to process conductive fibers like carbon. The researchers and students collaborate closely with the Stäubli Textile division, which provides technical assistance for sophisticated bindings, speedy support, and a wide range of services, always with one key objective in mind: to advance the world of technical textiles and allow this market to step ahead.

A selection of technical fabrics woven on the Stäubli TF weaving system can be seen at Booth D89 in Hall 12.0.

Weavers who want to produce technical textiles or who are planning to tackle a challenging weaving project are invited to schedule a talk with the Stäubli team in Frankfurt and find out more about the broad range of machinery designed for producing technical textiles.