#Spinning

Premiere for Retech at Techtextil Frankfurt

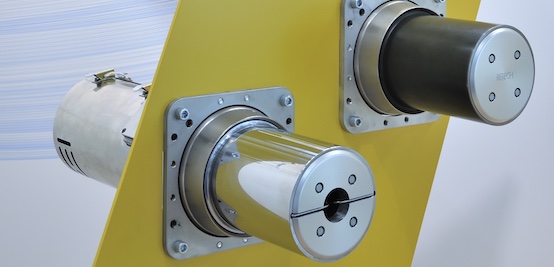

Pic: Retech heated godet rolls

Another highlight was the Win-OLT yarn tension sensor for the complete monitoring of DTY and or spinning machines for the improvement of quality in yarn production by means of on line monitoring. The performance range includes the complete system together with the necessary software, service and spare parts, as well as single yarn tension sensors.

The development of innovative, efficient and high quality draw machines built to the customers specification was discussed with several visitors and the modification, conversion and upgrading have also been vital topics. Integration of new technologies becomes essential in order to achieve sustainability in many respects including environmental protection, energy usage in combination with maintenance cost reduction and user-friendly operation.

Pic: Retech booth at Techtextil

For Retech it was the right decision to be at Techtextil Frankfurt. During the show, they could meet and discuss with many existing customers and also very important, new, potential customers showed interest in their products. Retech thanks everybody that visited the booth and is looking forward to future partnerships and collaborations.