Textile chemistry

Covestro: with renewable raw materials on the way to a circular economy

Covestro focuses on biomass as raw material and substitute for crude oil

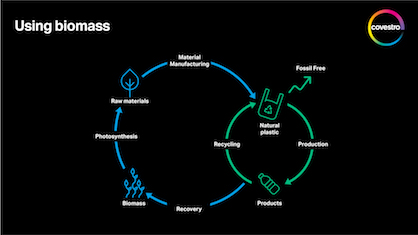

Biomass is a renewable resource that absorbs carbon dioxide from the air as it grows. It thus forms a reservoir for the important element carbon, which is needed to produce plastics. At present, this still comes mainly from fossil sources such as crude oil.

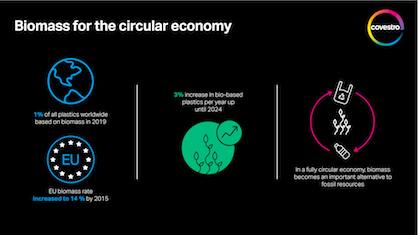

But biomass is on the advance. Currently, around one percent of the world's plastics are based on it. The market is growing by about three percent annually. Various sources are possible: classic industrial plants such as corn, rapeseed or sugar beets; but also increasingly straw, wood, algae or sawdust. And even food waste could become a new building block for plastics. If these are recycled at the end of the process, the carbon in them is circulated. This helps the climate and is the basic idea behind the circular economy, which must become a global guiding principle.

Covestro has been using bio-based raw materials for the development and manufacture of its products for years. In this way the company wants to come closer to its vision of complete circularity, but also to meet the rapidly growing consumer interest in sustainable products.

The product range includes a raw material for coatings, 70 percent of whose carbon comes from renewable resources. It is used in demanding applications such as automotive coatings and has already been successfully tested in a clear coating under near-series conditions. Covestro also offers ingredients for furniture coatings, some of which are produced from vegetable raw materials.

Biobased are also coatings for textiles and raw materials for cosmetics. The company has also developed a completely new film made of the high-performance plastic Polycarbonate, half of whose carbon is generated from biomass. It could be used in the automotive, electrical and consumer goods industries, for example.

European research

Ideas for many other biobased products are in the pipeline at Covestro. The company is collaborating on various research and development projects with partners from industry and science. For example, in the project to obtain the important plastic component aniline completely from plant biomass. For this project, Covestro and its partners have developed a completely new process. Following the breakthrough in the laboratory, it is currently being transferred to larger technical dimensions.

In addition, Covestro is involved in transnational research and development projects in Europe. For example, the EU-funded PERCAL project is investigating how organic components of municipal waste can be used as raw materials. For Covestro, the aim is to extract the chemical succinic acid in this way - as an ingredient of polyurethane dispersions for textiles and cosmetics, for example.

The EU-funded SMARTBOX project deals with the recycling of second-generation renewable raw materials such as lignin, cellulose or wood waste. Here, Covestro is working to produce a novel component for the manufacture of the high-performance plastic Polycarbonate. Finally, the BioCatPolymers funding project aims at the utilization of wood biomass such as wood chips or sawdust. This could be used to produce building blocks for thermoplastic Polyurethanes, for example.

Biomass-based products – a viable alternative

Plants and trees, but also organic waste, contain carbon that can be used as a more sustainable raw material for manufacturing plastics and chemical products. For years, Covestro has been using alternative raw materials of this kind to develop and manufacture its products. In doing so, the company wants to come closer to its vision of complete circularity, but also to meet the rapidly growing interest in sustainable products.

More and more consumers are paying attention to sustainable products. An important criterion is the origin of the raw materials used. Covestro has been working for years to replace some of the fossil building blocks used up to now with renewable ones. In this way the dependence on crude oil can be reduced. The biomass binds CO2 during its production and thus additionally reduces the ecological footprint. However, a prerequisite for a successful market launch is also that bio-based products show at least the same good properties as petrochemical-based materials and can seamlessly replace them in current production.

Sophisticated automotive paint

One example of this trend is a paint hardener whose carbon content comes from 70 percent renewable raw materials. It is used in demanding applications such as in automotive paints and has already been successfully tested in a clear coat under near-series production conditions. The clear coat, which forms the top layer of automotive paint, is scratch resistant, glossy and weather-resistant. In this context, the hardener Desmodur® eco features the same positive qualities as similar fossil-based products. Another clear coat using this hardener even survived unscathed after a 3,000-kilometer trip under the blazing sun through the Australian Outback.

Water-based textile coating

Aqueous coatings also play a major role in the textile industry and are increasingly replacing solvent-based systems in order to protect the health of employees. Now the water-based raw material Impranil® eco is also available for coating textiles, whose carbon content is based on up to 56 percent plant biomass, replacing a portion of the fossil raw materials previously used.

Versatile films

A new film made from the high-performance plastic polycarbonate is also produced partly from biomass: It replaces around 50 percent of the carbon content. Makrofol® EC is the first commercially available plastic product of this type from Covestro. It meets the requirements for polycarbonate films made from petrochemical raw materials and even exceeds these requirements to some extent. Possible applications include the automotive, electrical and consumer goods industries. Covestro is currently working on expanding its existing product portfolio, including for partially bio-based thermoplastic polyurethane (TPU) films of the Platilon® and Dureflex® grades. TPU plastic products with biomass are already available on the market, some of them can also be used in 3D printing applications.

The future: a broader raw materials base

While many of these products are produced using plant-based ingredients, Covestro is already working on broadening its biological raw material base in the scope of its current research projects. In the future, the company could also use municipal organic waste and waste wood to develop sustainable products.

Europe-wide cooperation for biomass for plastics production

Several countries, numerous partners, different abilities – with this recipe for success, new applications for plant biomass in chemical production are being worked on in Europe-wide projects. The materials manufacturer Covestro is involved in three initiatives – with the aim of avoiding fossil raw materials for plastics, and thus making its own products and their production more sustainable.

The chemical and plastics industry must become less dependent on fossil resources such as crude oil. Because their reserves are limited and their use releases climate-damaging CO2. A promising alternative is vegetable biomass. It can also provide the element carbon, which is needed for plastics. The possibilities here are far from exhausted.

In order to explore new paths, transnational research and development projects are underway in Europe, for example, in which the materials manufacturer Covestro is involved. The aim is to make plastics production significantly more sustainable through a better carbon footprint and to contribute to climate neutrality. In addition, the carbon is circulated in this way, which promotes the transition to a circular economy.

Using municipal waste

Since July 2017, Covestro and eleven other partners from eight European countries have been working together in the EU-funded research project PERCAL. This project is investigating how organic components of municipal waste can be used as raw materials. For Covestro, the aim is to extract the important chemical succinic acid in this way. Succinic acid in turn is needed to produce building blocks (polyols) for polyurethane dispersions, which could then be used in textiles and cosmetics.

Advancing the second generation

The EU-funded SMARTBOX project is concerned with the utilization of second-generation renewable raw materials such as lignin, cellulose or wood waste. It has been running since May 2019 and, in addition to Covestro, includes ten companies and academic institutions from eight European countries. The partners aim to create high-quality products through the use of biotechnology and computer-aided methods. Covestro is working on obtaining a novel building block from biomass for the production of the high-performance plastic polycarbonates.

Extracting chemicals from wood

In the BioCatPolymers project, which was launched in January 2018, Covestro and six other partners from five countries are researching the utilization of wood biomass such as wood chips or sawdust for the production of biobased chemicals. Among other things, the aim is to obtain building blocks (polyols) for thermoplastic polyurethanes (TPU).

Live webcast with media

In an interactive live webcast, Covestro discussed current developments and future perspectives for the use of biomass. Dr. Christian Haessler, head of the global Circular Economy program, and Dr. Vera Eßmann, expert for renewable resources, explained how Covestro uses renewable resources along the value chain together with partners and opens up new sources of raw materials, including from biowaste, in international R&D projects. Furthermore, they introduced a broad portfolio of marketable bio-products for many industries Covestro already offers. The renowned biomass expert Professor Henk Noorman from the Technical University and the DSM Biotechnology Center in Delft, the Netherlands, was also present. He introduced the carbon-loop value cycles driven by renewable energy to the audience.