#Spinning

2Impact FX: Innovation update for ultraeconomical compact spinning technology

The new air ducting system ensures a turbulence-free airflow with positive effects on the compacting of the yarn. The air circulates freely around the 2Impact FX unit, so that there is no tendency towards contamination from additional machine elements as is the case with the competition. The core of Zinser compact technology – the self-cleaning compact apron – has been improved in one important detail. With its inclined slots it has better running properties, which increases the service life of the apron.

No loss of compact power

The economic efficiency of compact spinning stands or falls with the compact power of the system. Only if the airflow that binds the fibres into the yarn remains constant during the entire spinning process is it possible to create a product of guaranteed quality and to fully exploit the economic advantages of compact spinning.

In competitor systems compact power is lost because the air ducting systems become clogged with fibre particles during spinning. This reduces the vacuum in the compacting unit and the yarn gradually loses its desired characteristics. The consequence is a steady drop in quality. In addition, personnel-intensive inspections and time-consuming cleaning intervals are required. By contrast, in the 2Impact FX there is no loss of compact power.

The self-cleaning system continuously ensures the desired yarn quality. There is no need for personnelintensive inspections. There are also no production downtimes due to cleaning intervals.

Compact spinning is becoming increasingly popular

The trend towards compact spinning continues to grow and will become even stronger over the course of the coming years because of its compelling economic benefits. With Zinser 2Impact FX technology these benefits can be fully exploited. The technology represents an innovative milestone offering 100% compact power, ultimate reliability and maximum economic efficiency.

The most intelligent system on the market

The compact spinning system from Zinser is the most intelligent on the market. It is

- automatically self-cleaning,

- optimally aerodynamically designed and

- equipped with its own controlled vacuum unit.

The innovation edge provided by 2Impact FX offers Schlafhorst customers all the benefits of compact spinning.

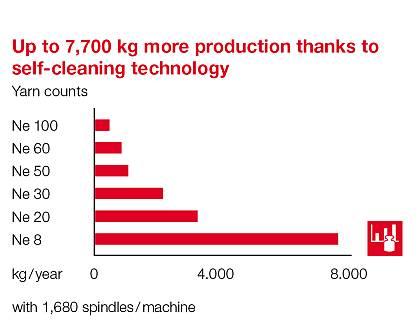

Superior cost effectiveness through increased production

With 2Impact FX, the second generation of compact spinning innovation from Schlafhorst, the company enhances its selling proposition in terms of economic efficiency and quality. The Zinser 351 2Impact FX is the result of systematic customer-oriented product development. The innovative compact spinning machine increases customer benefit in areas crucial to success. No personnel are needed to check the compacting unit and production is not interrupted by cleaning intervals. Depending on yarn count and machine length, selfcleaning 2Impact FX technology enables operators to achieve production increases of up to 7,700 kg per year just through the absence of cleaning intervals.

Self-cleaning technology based on innovative milling effect

The secret behind the success of 2Impact FX is its self-cleaning technology. Thanks to its intelligent design, fibre residues and other dirt particles are expelled out of the air openings by the milling effect at the compacting apron's deflection points. The airways in the compacting unit remain open during the entire spinning process and a constant vacuum is ensured. In the case of competitor systems that work with rigid screening drums, the openings become congested with fibre residues and clog up over time. As a result the crosssection of the air openings, and therefore the vacuum, is constantly changing. Compact power is therefore lost and constant compact quality is impossible. By contrast, 2Impact FX guarantees full compact power metre after metre, spindle after spindle, lot after lot.

Guaranteed compact power thanks to integral vacuum unit

Unlike other systems, 2Impact FX has its own controlled vacuum unit that works independently of the yarn break suction system. This prevents the compact power from being absorbed by the suction system. With 2Impact FX the setpoint value for the compacting vacuum only needs to be entered once via the userfriendly EasySpin touchscreen. The control system with vacuum sensor and independent, frequencycontrolled motor continually ensures the desired actual value. Constant compact power for constant quality.

The self-cleaning technology and integral vacuum unit of 2Impact FX complement each other and together guarantee constant compact power and therefore the constant quality of the compact yarn. This innovative "in-built quality control" is typical for Schlafhorst – and results in additional customer benefit and additional customer satisfaction.

Standard components simplify servicing

Schlafhorst also offers additional customer benefits through other design advantages. For example, with 2Impact FX the same components are used at each spinning unit since, unlike competitor systems, the components do not change in terms of their specifications along the machine. There is therefore no risk of confusion when replacing parts on the 2Impact FX. Staffing and logistics costs are also reduced compared to the competition.

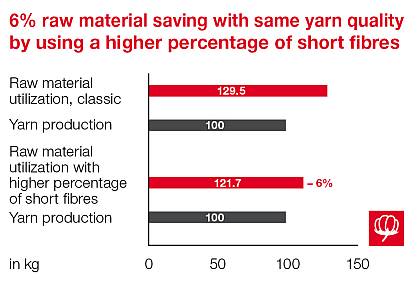

Reducing raw material costs

The economic advantages of compact spinning with 2Impact FX have already been mentioned several times. However, not everyone is aware of the advantages compared to simple ring spinning. It therefore makes sense here to highlight once more the higher economic efficiency of compact spinning with 2Impact FX.

Innovation management with global network

With the Zinser 351 2Impact FX, Schlafhorst has again succeeded in extending the technological possibilities of its unique product line and positioning itself to meet future market requirements. And this hasn't happened just by chance. With 150 engineers and a global network of universities, service centres and technology centres, Schlafhorst innovation management points the way forward. Schlafhorst continuously monitors the textile markets of the world so that it can respond proactively to the dynamics of market demands. It is therefore able to identify new customer requirements and market trends at an early stage – and to be the first company in the market to meet them thanks to continuously optimised innovation processes and a vital culture of innovation. Good news for all customers of this leading German manufacturer.