#Spinning

Forward-thinking and transparent communication keeps Loepfe ahead in delivery fidelity

Positioning themselves for future growth, Loepfe have made several key strategic moves to allow them to continue their mission to champion customer-centricity. Loepfe report that committed customer orders are being delivered on time, making them a reliable partner within the very uncertain business environment. Loepfe consider transparent communication and their collaborative approach with all the involved parties as main success factors.

Delays in international sourcing has been the downfall for many market players, however, Loepfe are committed to sourcing with a future vision to ensure that customer expectations can still be met. Clearing sourcing bottlenecks, holding increased stocks, and building closer working relationships with both new and existing suppliers, as well as customers, has allowed them to gain additional business against a challenging procurement backdrop. Also, strengthening relationships with transport partners and increasing the use of air freight has helped Loepfe fulfil their commitments.

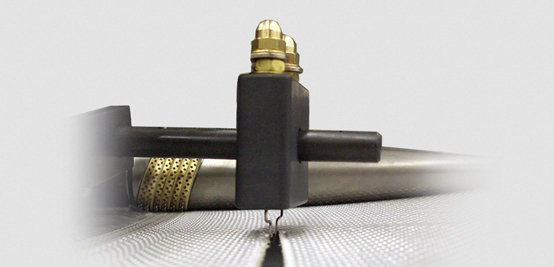

Further, Loepfe’s broad product range has played a crucial part. With more complete product families, they have the flexibility to use multiple products to fit the needs of the customer. The respective product components are sourced independently from long-standing suppliers, and product production runs in parallel thanks to successful recruitment and new employment models. Swiss-made hardware quality along with the offering of software updates give products greater longevity and the ability to adapt to changing demands.

However, all these initiatives have come with higher cost pressure and increased capacities and have required a great level of dedication and flexibility from every individual in the Loepfe team and its partners. In an ever-changing landscape they recognize there is no room for complacency and remain committed to evolving their processes to ensure customer satisfaction.

Dr. Ralph Mennicke, CEO of Loepfe Brothers Ltd. said: “We are delighted we have been able to fulfil our commitments to customers, old and new. We are constantly looking for innovative ways to retain our strong position. There are many pressures in the market right now, and our strong position has required a great deal of foresight, dedication, and troubleshooting. While full availability of all components in our complex sensor products cannot be taken for granted nowadays, we are making the utmost efforts to ensure transparency to our partners and to find solutions along the way that meet our customers’ needs. I’m grateful to every individual in our team who has helped to make this happen. We remain committed to our long-standing clients and look forward to welcoming even more new customers into the Loepfe world.”