#Spinning

Loepfe yarn clearers are our best choice states Xuzhou Huasheng Textile co ltd. China

Yarn spinning production in China is today confronted with rising wages, higher energy bills, shortage of labour and mounting logistical costs. The combination of these reasons is leading Chinese spinning companies to invest in machineries offering a higher degree of automation in their mills. The trend towards automation and digitalization significantly determines investments of the textile industry, both in new installations and in the replacement sector.

Spinning mills that still work manually today with shorter spinning machines upgrade into economical automation thanks to the multi-link winding solutions, which makes it possible to assign several ring-spinning machines to a winder, which makes such link upgrades profitable with shorter spinning machines as well.

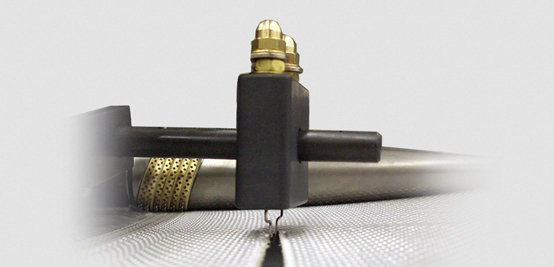

Xuzhou Huasheng Textile Co. Ltd. has taken up this economical automation solution to stay competitive in the future and has just recently invested in 12 Savio Polar IDSL multi-link winders having up to 70 spindles with Loepfe YarnMaster ZENIT+D basic yarn clearers. At this mill, the foreign fibre cleaning functionality is not an issue with pure Viscose, Modal, Lyocell fibres and blends thereof processed. Each winder is linked with 3 different ring spinning machines.

Xuzhou Huasheng Textile Co Ltd. is a privately held spinning company located in Peixian which is under the administration of Xuzhou, Jiangsu Province, China, bordering the Shandong prefecture level cities of Jining to the northwest and Zaozhuang to the northeast and sitting on the western shore of Nansi Lake.

Established in the year 2000 and headed ever since by Mr. Zhang Yu Meng, Vice General Manager and General Manager for Production, Xuzhou Huasheng Textile Co. Ltd. quickly became the leading quality ring spinning mill in this area with 250’000 spindles offering an annual production capacity of 40’000 tons. Xuzhou Huasheng Textile Co. Ltd. is focusing its activities primarily in the Siro spinning of Viscose, Modal, Viscose Modal and Viscose Lyocell blended yarns as well as slub yarns in the yarn count range of Ne 10 – Ne 100 for knitting and weaving fabrics.

Mr. Zhang Yu Meng quotes: “To be successful in the long term in the highly competitive Viscose yarn market, it is extremely important that we are perceived as a supplier of constant yarn quality. Our long-term customers expect from us that we deliver constant yarn quality with every order. We’re working hard daily to achieve this reputation in the market and Loepfe’s yarn clearers of various generations with its unique Lab Pack quality assurance function help us greatly to achieve this! We are processing all our yarns on more than 3’000 winding positions in our mills having all optical yarn clearers from Loepfe from various generations. On all our yarn clearer systems, the activated Lab Pack quality assurance option and its bad bobbin detection is making sure that we can always deliver constant quality yarns to our customers.”

100% Online quality assurance and detecting off-standard bobbins

The philosophy of 100% online quality assurance in the winding process, introduced by Loepfe into the spinning mill world years ago, provides all relevant quality test characteristics except for tensile strength tests. Experienced spinning mill managers no longer rely on random samples! Even when a production lot was found good using time-consuming laboratory verifications, strikingly divergent off-standard bobbins give cause for complaint. These problems can be avoided with Loepfe’s Lab Pack quality assurance function, as it eliminates reliably off-standard bobbins from production and always keeps the yarn quality constant due to fixed and comprehensive clearing limits in a pre-set range.

Lab Pack online laboratory data needs data management

At Xuzhou Huasheng Textile Co. Ltd., all the data from all the various yarn clearers from all winding machines is processed with Loepfe’s MillMaster TOP monitoring system. However, the fact that important yarn quality data such as hairiness, neppiness, general yarn surface irregularities and diameter variations, besides the normal yarn imperfections are made visible, a comprehensive quality monitoring and analysis is at the disposal for the customer. A very important advantage with basic yarn clearers unlocked with Lab Pack function such as YarnMaster ZENIT+D, as the single optical infrared sensor is capable to monitor all these parameters without the necessity of an additional foreign fibre sensor!

Only the Lab-Pack functionality and the simultaneous processing of all data generated by the yarn clearers with Loepfe's MillMaster TOP data management system complete the seamless quality monitoring. The edited quality reports are used to intervene in time in the spinning mill process. By analysing the quality reports, service and maintenance work can be optimized, which, apart from a constant quality, also results in cost savings.

Final words of Mr. Zhang Yu Meng from Xuzhou Huasheng Textile Co. Ltd: “To push the automatization possibilities forward and to benefit from todays and future digital solutions are important parts of our corporate strategy. The MillMaster TOP monitoring system from Loepfe is connected to all our existing Loepfe yarn clearers, which are activated with the LabPack function on our Savio winding machines. This results that we always have reliable production and comprehensive quality data on 100% of our yarns available. We and ultimately our customers not only benefit from a constant yarn quality through this combination, but it also enables us to economically optimize processes and the use of raw materials. The company’s present and future success depends on the ability to embrace such technological possibilities!”