#Spinning

Setting new quality standards with preciforce™

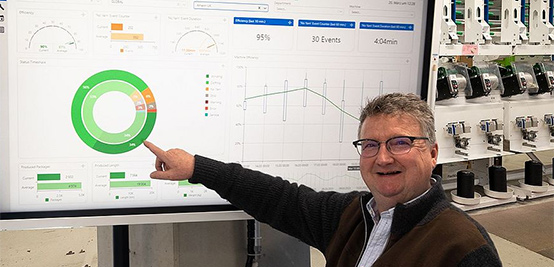

In day-to-day operation the company works with around 20 000 spindles, including 331 SSM winding spindles, whereof 45 are equipped with preciforce™. In an interview, Oliver Kächler (Plant Manager), shared some interesting insight how SSM’s high precision backpressure system helped Gebrüder Otto to grow its business.

Mr. Kächler, what was your challenge and why were you convinced that SSM could help to achieve your results?

We use some of the yarns to produce dye packages which are very difficult to process perfectly. Therefore, we were looking for a machine that can do this and meets the highest quality standards in the industry. We went to SSM because of their reputation as the market leader when it comes to high competency in winding technology.

How did you overcome the challenge and what was the most significant improvement for you?

Thanks to the new preciforce™ backpressure system, we have been able to achieve very low winding densities and at the same time very high consistency of density from package to package. With the SSM machines, we are now producing dye packages with perfect quality, even with the most difficult yarns – and that’s exactly what our customers expect and demand from us. But the production quality is not the only benefit – we have also been able to significantly improve our productivity in this important business area. SSM has been a great partner for Gebrüder Otto, helping us to grow our business in terms of quality and productivity.

Are you satisfied with the services provided by SSM and their machinery installations?

SSM has always been there for us and we are in good hands. From our initial inquiry to consultation, product selection, machinery installation, commissioning, training, and after-sales service. They handle each step in an uncomplicated manner, and their response time has always been very short.

Would you choose SSM machines for your next production expansion projects, and would you recommend them to a friend?

Yes, absolutely. SSM is the first-choice partner for cone-to-cone winding technology.