#Spinning

MillMaster Labtrend Simple control of wear and tear

Deviations in the yarn quality produced may result from the following factors:

- Raw material change

- Settings change

- Wear and tear

- Dirt

- Climate changes

The following examples outline how the maintenance interval for wear parts can be planned and the correct selection of components can be made.

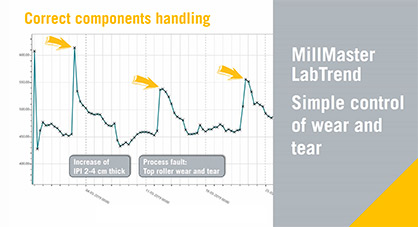

Figure 1 shows repeated IPI peaks in the range of 2 - 4 cm IPI Thick. This yarn’s irregularity pattern suggests increased wear and tear of the top roller surface due to e.g. constant friction or small grooves along the roller eventually affecting its surface structure. This is a slow, ongoing wear and tear process, which can easily be tracked with the help of “Lab Trend” in MillMaster TOP. The more the top rollers are suffering wear and tear, the more 2 - 4 cm IPI irregularities there will be in the yarn structure. Once there is an excessive increase in IPI values, it is time to take appropriate action.

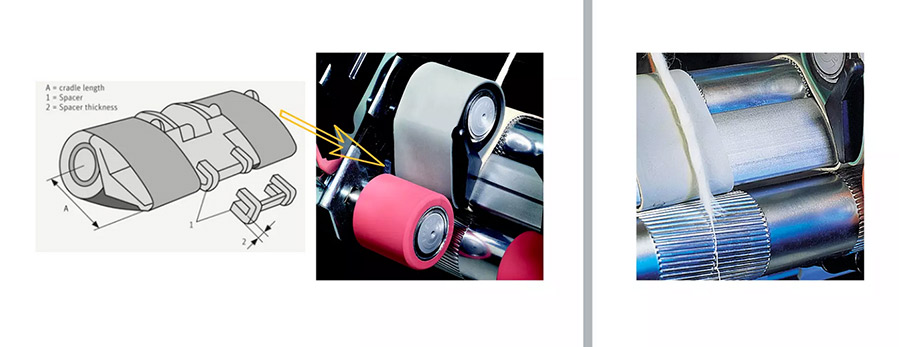

MillMaster TOP not only helps in identifying wear and tear but also helps towards the selection of the right machinery components, e.g. to determine the optimal cradle spacer for the top roller.

The cradle spacer is used to optimize the main drafting zone of each ring spinning position. The selection of the right cradle spacer sometimes requires a few iterations until the optimum is found.

MillMaster TOP’s “Lab Trend” can easily visualize the influence of the used cradle spacer type and in due course contribute to achieving an optimum. This is done in real time by evaluation of 2 - 70 cm IPI Thick events, whereas the different sizes of the cradle spacers directly influence the number of these undesired thick places.

Likewise bottom apron types of various suppliers can be compared in terms of the resulting yarn quality.

Also here “Lab Trend” can easily show how different condition or quality of bottom apron types might affect the yarn irregularity and help finding the best-suitable option.

Solutions & benefits:

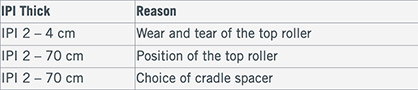

MillMaster TOP “LabTrend” significantly helps to identify the reasons for quality deviations and their causes without much effort. Following table provides a brief overview of the IPI influencing factors mentioned in above outlined examples.

MillMaster TOP "LabTrend" not only allows comprehensive monitoring and evaluation of the yarn quality, but also supports maintenance planning, monitoring of the machine settings and the selection of the best-suitable machine accessories.