#Spinning

MillMaster LabTrend offers new functions and more benefits

Deviations in the yarn quality produced may result from the following factors:

- Raw material change

- Settings change

- Wear and tear

- Dirt

- Climate changes

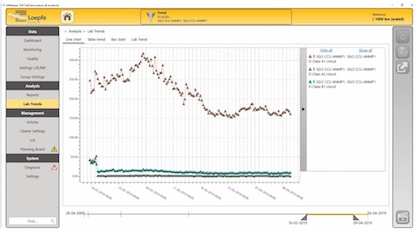

The “Lab Trend” collects various data and displays trends, based on the following data items:

- Cut

- Imperfections

- Hairiness

- Evenness

- Yarn classification

Each “Lab Trend” report contains a graphic representation of the quality fluctuation. This easily visualizes the progression over time.

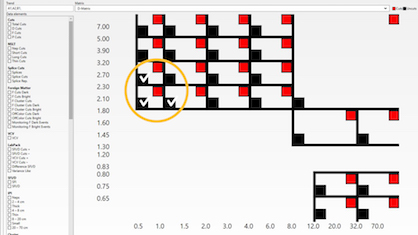

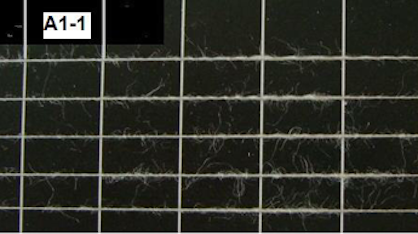

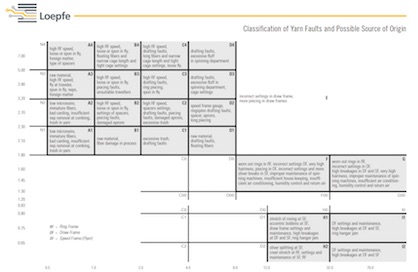

An overview shows the yarn class in which the quality deviation occurs and a sample representation of the yarn defects within the respective yarn class.

Solutions and benefits

The extensive information of the “LabTrend” can now be compared with the “Classification of yarn faults” matrix. This allows for precise identification and fast correction of the causes responsible for the encountered quality fluctuations, from raw material throughout the various preparation stages and up to the ringspinning process, ultimately providing complete control over the whole production process.

MillMaster is a great tool for any spinning mill tackling their daily quality and production challenges. It’s “LabTrend” not only allows for a fast and well-aimed action, but it also leads to a constant yarn quality and provides the basis for efficient machine maintenance, eventually also leading to a significant reduction in maintenance costs.