#Spinning

Loepfe presents brand-new yarn clearer generation

The Yarnmaster Prisma opens up a new world at ITMA 2019

Four sensor technologies interact intelligently and ensure unprecedented fault visibility and data quality. The unconventional new concept addresses all yarn quality problems related to material and the spinning process with an universal and multi-dimensional approach.

Four sensor technologies

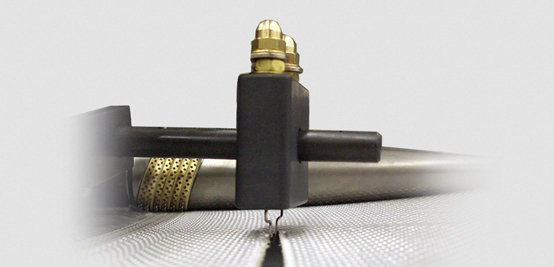

Controlling the contamination in yarns is of greatest importance to the spinners. The YarnMaster PRISMA utilizes a sensor for foreign matter detection based on a brand-new RGB-color measuring technology. The new RGB F-sensor illuminates the yarn in the full spectrum of light, enabling the recognition of even the slightest difference in shade and glossiness in any type of yarn and color. The contamination of raw material with white polypropylene from bale packaging is very challeng-ing. To solve this difficult task, Loepfe developed the P4-Sensor, which utilizes the triboelectric effect. The sensor measures electric charge differences, which are caused during the winding process by different raw materials. This technology is able to detect contami-nation with white polypropylene very reliable. Beyond these, a world first dual measurement for basic clearing is presented to the visitors. On the YarnMaster PRISMA, the two dominant sensor technologies in yarn clearing are integrated into one single sensing head.

This uncon-ventional approach to use an optical and a mass sensor, functioning in perfect harmony, offers unprecedented possibilities and new levels of precision in yarn clearing. The fusion of four sensor technologies into one single sensing head –- YarnMaster PRISMA – guarantees previously unachieved performance and possibilities in quality control during the winding process.

A world of connectivity

The heart of the innovative yarn clearing concept is the simple and intuitive PRISMA operating system. The new PRISMA GUI offers a menu guidance by an intel-ligent wizard and enables straightforward and intuitive operation. As an extra benefit, Loepfe’s data management system MillMaster TOP 2.0 is an integral part of the new YarnMaster PRISMA and complements every Loepfe yarn clearer installation. 100% online monitoring of quality data produced by the yarn clearers reduces the need for routine laboratory tests. Effective online quality management is one of the key success factors for win-ding and results in efficiency and lower costs.