#Software

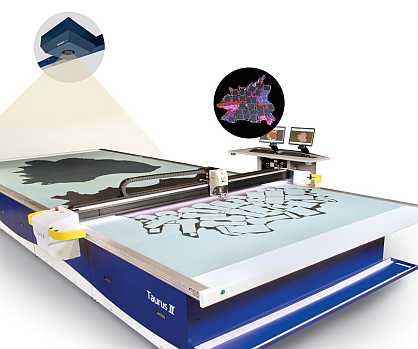

Gerber Technology’s new Taurus II Leather Cutting System delivers up to 10 percent improvement in hide yield

Gerber’s RapidScan™ software technology is embedded in a state-of-the-art digital camera mounted above the cutting table which captures hides of all colors in seconds without time-consuming calibration. To mark flaws, inspectors use a single color marker to draw symbols on hides that identify up to four flaw zones. Multiple colored tape or markers are not necessary.

“We’ve packed our nearly two decades of nesting and leather cutting expertise into this extremely efficient system and priced it at a fraction of most automated leather cutting systems,” noted Tom Gordon, senior product manager for Gerber. “At the core of Taurus II is an extremely powerful computerized nesting engine developed and refined by Gerber that has more than one million nesting strategies at its disposal.”

Efficient leather cutting using dies is dependent on an individual’s capacity to visually analyze the shape of a hide and determine the most efficient placement of dies or templates to optimize hide utilization. This process is essentially subjective and can fluctuate from day to day or person to person. It can be challenging to find individuals who are experienced in nesting parts efficiently to maximize hide yield. When skilled workers are available, they command higher wages than non-skilled workers. Because Taurus II nests parts automatically and is easy to learn and use, companies not only reduce labor costs significantly by hiring fewer skilled workers, they also get consistent results that are not dependent on the performance of one or two individuals.

Comprehensive data also enables managers to track work in progress and identify opportunities to improve processes. Taurus II digitally records the details of every hide, including usable area and defect area. Users can then compare these figures with those stamped on the back of hides and negotiate more effectively with hide suppliers.

Taurus II is available in one- or two-station configurations that enable users to maximize their existing floor space. The single-station Taurus II offers the smallest footprint for flexible facility planning. The Taurus II dual-station system offers maximum production output with the highest return on investment in the industry. The two-station system enables users to cut on one station while preparing a hide or offloading cut parts on the other to maximize productivity of the system. Both configurations accommodate full hides, half hides and remnants.

“In the end, Taurus II helps customers improve their profitability by reducing labor and material costs, saving time and helping produce the best quality product possible,” Gordon added.

Pic: Taurus II with cam