#Software

Gerber partners with 3DLOOK to offer unique digital customer experience

Offer the ultimate experience of the end-to-end supply chain remotely.

To support demand from smaller, made-to-measure companies whose businesses have relied on the traditional way of measuring customers in person, 3DLOOK has developed a special package with very quick and easy integration. The goal of the integration is to give small businesses the digital tools they need to operate online and meet customer demand, all while remaining digitally competitive and forward-thinking in an era that requires constant technological evolution, regardless of business size.

“We are incredibly proud to partner with 3DLOOK to offer worldwide brands and retailers a fresh, digitally innovative way to collaborate,” said Ketty Pillet, VP of Marketing at Gerber Technology. “For companies to truly offer their customers the best quality products, they need to ensure that their clothes fit perfectly.”

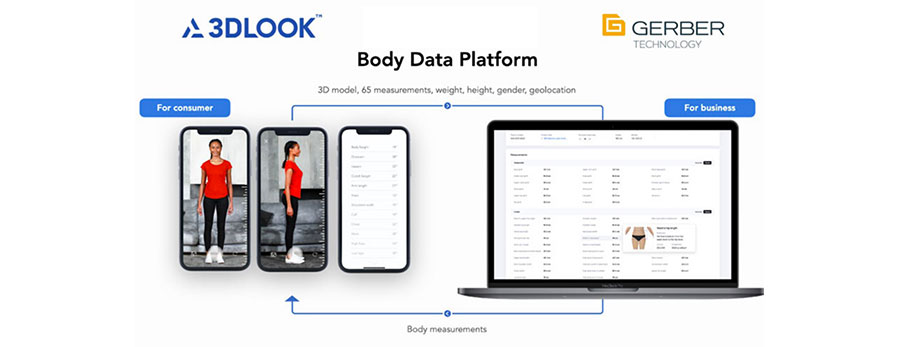

The Body Data Platform maps body data to product data, transactional data, and product return data to deliver analytics related to measurement, shape, 3D model accuracy, and fit, as well as customer profile insights through a dynamic dashboard. Customers take two photos while fully clothed, and a computer vision algorithm then detects the human body and renders 3D models and body profiles. The algorithm measures the 3D models to compute 65 ISO-compliant measurements. By using 3DLOOK’s platform, customers can easily understand how the garment will fit on their unique body shape.

"We see this partnership as the first step towards providing brands, manufacturers, and retailers with the digital tools needed to support a full end-to-end customization platform which meets the needs of customers increasingly focused on products personalized to their fit and preference and who also care about supporting more sustainable supply chains and business models,” said Whitney Cathcart, CSO & co-founder of 3DLOOK. “By integrating our widget into Gerber's "Made For You By You" flow we are enabling a simple way to digitize measurement capture and automate the workflow process."

For many consumers, fit is a deciding factor in choosing which brands to buy from. In fact, according to Mintel, 81% of consumers who buy clothes that fit right are much more likely to buy from that brand again. It is critical for today’s fashion companies to prioritize fit in their design process to eliminate guesswork for their customer and reduce the number of returns. 3DLOOK's Body Data Platform provides the insights and analytics to help brands optimize their fit and grading systems from broad segmentation based on historical surveys to real-time segmentation focused on their unique customers.

Thanks to the newly-added 3DLook integration, visitors to the virtual Gerber Innovation Center can access Gerber’s YOU website from anywhere in the world to customize garments to their individual fit preferences and measurements. These virtually customized garments can then be digitally brought to life -- incorporating the customer’s preferences -- through Gerber’s fully-connected microfactory, giving them a fully-realized, production-ready garment. Gerber’s partnership with 3DLOOK will enhance the overall fit of the final garment, offering customers an even more personalized digital experience.