#Recycling / Circular Economy

A broad range of advanced recycling technologies keeps carbon in the loop

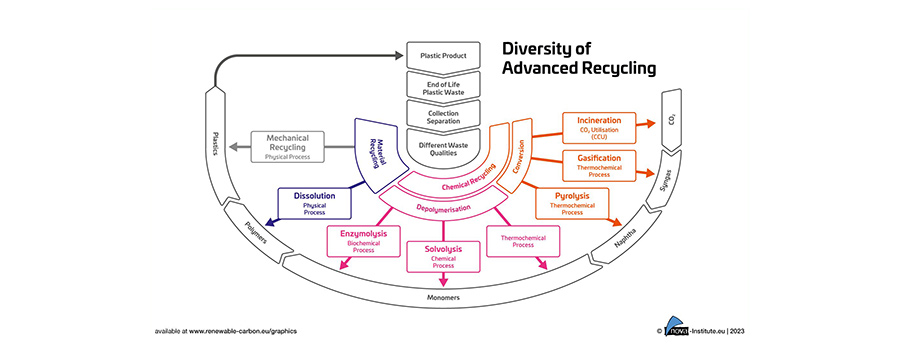

Following its successful premiere in 2022, the Advanced Recycling Conference 2023 (http://www.advanced-recycling.eu) will present the broad range of advanced recycling solutions from extrusion, dissolution, solvolysis, enzymolysis, pyrolysis, thermal depolymerisation, gasification, to pre- and post-treatment, upgrading, and reactive extrusion, but will also address related topics like policy, LCA, and mass balance approach in recycling.

With currently approximate 88 % of embedded carbon coming from fossil feedstocks, including oil, natural gas and coal, it becomes evidently clear that the estimated future demand of 1.15 Gt of carbon per year by 2050 must be met exclusively by the three available renewable carbon sources: biomass, the direct use of CO2 and recycling. While biomass solutions frequently face the food vs. feed debate, Carbon Capture and Utilisation (CCU) efforts are not receiving the required policy support to develop at a rapid pace. Here, advanced recycling solution can contribute significantly to keep and reuse embedded carbon in the technosphere.

From plastics to textiles and LCAs of recycling feedstock – A fully rounded program of innovative recycling solutions

At the same time, with a variety of legislative initiatives under the Green Deal, the EU is working on setting high mandatory recycled content quotas for many products – from packaging over textiles to cars and others. Recently leaked ambitions on mandatory recycled content for packaging aim at a ten-fold increase in the use of recycled material in this sector by 2040. In order to keep up with these requirements and still provide economically feasible high-quality materials and products, companies must stay up to day with regard to innovative advanced recycling solutions. The international program of this year’s Advanced Recycling Conference presents technologies capable to address waste streams that are difficult to recycle including mixed plastics packaging and textiles aside others, with international contributions from industry, policy and academia addressing various recycling hot topics. Find the full program at https://advanced-recycling.eu/program/.

Day 1, 28 November 2023

10:00-17:40 (CET)

Policy, Markets, and Strategy

Understanding what political foundations have been laid for a meaningful transformation of the circular economy, and what are the challenges? Which markets show the most promising prospects for investment and what strategies can lead to success?Michael Carus, nova-Institute (DE): Importance of Advanced Recycling for the Renewable Carbon Economy

• Lars Krause, nova-Institute (DE): Advanced Recycling Overview and Worldwide Capacities

• Lara Dammer, nova-Institute (DE): From Mass Balance to End-of-Waste Criteria: What’s New in Policy for Advanced Recycling

• Luis Hoffmann, Sulzer (CH): How Collaboration Enables Circular Plastic

• Dimitri Daniels, Der Grüne Punkt (DE): Mechanical and Chemical Recycling to Achieve Circularity of Plastic Packaging

Pyrolysis

Pyrolysis is a versatile tool that is able to complement mechanical recycling and to produce a wide range of different products that can be utilised in the chemical and plastics industry. Collaborations between all stakeholders are therefore necessary and meaningful to improve the circular economy of plastics.

• Carlos Monreal, Plastic Energy (UK): Supporting a Circular Economy for Plastic Waste Through Chemical Recycling

• David Sudolsky, Anellotech (US): Recycled BTX Made From Mixed Waste Plastics via Plas-TCat® Process

• Oliver Borek, Mura Technology (UK): Mura Technology: Key Advantages of Hydrothermal Liquefaction

• Christian Haupts, Carboliq (DE): A Roadmap Towards TRL 9 in Chemical Recycling – The Knapsack 10 kta Plan(t)

• Valentijn de Neve, BlueAlp (NL): BlueAlp – Accelerating Plastic Recycling

Dissolution

Polymer extraction from plastic (multilayer) packaging and other materials through dissolution and the selection of suitable solvents for the process.

• Abidin Balan, Trinseo (NL): Dissolution Technology: An Approach for Infinite Circularity

• Matthias Wilhelm, Lober (DE): Dissolution Recycling as a Solution for a Multilayered Problem

• Florian Riedl, APK (DE): High-Quality Recyclates from Post-Consumer Flexible Packaging Waste via the Solvent-Based Newcycling Technology

• Panzheng Zhou, University of Wisconsin-Madison (US): Computational Modeling of Dissolution-based Plastic Recycling: Solubility Prediction, Solvent Screening, and Process Design

Versatility of Extruders (Pre-treatment and Reactive extrusion) & Advanced Mechanical Recycling (Parallel-Session: no online transmission)

Versatility of Extruders (Pre-treatment and Reactive extrusion) & Advanced Mechanical Recycling (Parallel-Session: no online transmission)

Extruders are not only known in the world of mechanical recycling; they can be utilised as reactor or pre- and post-treatment units in advanced recycling. Depending on the composition and type of polymer different processes may be necessary or more suitable for which a large toolbox of advanced and mechanical recycling technologies can be accessed.

• Klaus Lederer, Erema Group (AT): Advanced Input Stream Preparation Technologies for Chemical Recyclers

• Belén Monje, Aimplas (ES): Reactive Extrusion Potential in Recycling and Repolymerization

• Frank Eisenträger, INEOS Styrolution (CH): Advanced Mechanical Recycling of Polystyrene

• Lars Biermann, KraussMaffei Extrusion (DE): Closing the Material Loop of Polyethylene

Day 2, 29 November 2023

• Lars Krause, nova-Institute (DE): Conference Opening

Depolymerisation

Assisted by heat, radiation, the use of catalysts or addition of chemicals and enzymes, the depolymerisation breaks plastic waste, and even textiles into its building units (e.g. monomers) that can be fed back into polymer production. Learn more about solvolysis, Enzymatic recycling and the detoxification of contaminated plastics.

• Fabio Silvestri, gr3n (CH): We MADE it! Towards Tangible Changes in the Plastic Industry

• Vladislav Jaso, TotalEnergies Corbion (NL): Advanced Recycling of Luminy Poly Lactic Acid (PLA)

• Cecilia Mattsson, RISE Research Institutes of Sweden (SE): DeToxoLys – Detoxification and Recycling of Contaminated Plastic Waste Streams with Hydrothermal Liquefaction (HTL)/Solvolysis

• Stefan Schonauer, RWTH Aachen University (DE): Enzymatic Recycling of Textiles

Gasification

In contrast to incineration and energy recovery the gasification coupled with downstream processes opens new pathways for highly contaminated and very heterogenous waste streams. With the production of syngas and its processing in further downstream processes new paths are being taken for the production of chemicals and fuels.

• Freya Burton, LanzaTech, Enabling a Circular Economy: Low Carbon Fuel and Chemical Production from Waste

• Stephan Renninger, Cyclize: Zero Emission Waste Reforming to Enable a Circular Carbon Economy in Europe

• Cecilia Hofmann, Re:Lab: Gasification and Pyrolysis of Plastic Waste Under a Circular Economy Perspective: A Literature Review

Pre-/Post-treatment & Upgrading (Parallel-Session)

Pre-processing, post-processing, and upgrading technologies are connecting elements (enablers) to all advanced recycling technologies. The here introduced processes realise higher yields and achieve higher product qualities while bringing recycling to another level.

• Tobias Rieger, Fraunhofer UMSICHT (DE): Application of a Novel and Cheap Post-Reforming Agent to Produce High-Quality Aromatic Bulk Chemicals from MSPW Pyrolysis Oils and Dehalogenation Thereof

• Trine Dabros, TOPSOE (DK): Hydrotreating of Plastic Pyrolysis Oil: How to Maximize the Learnings From the First Industrial Plant

• Beate Kummer, Polysecure (DE): New Sorting Technology for Fractions to Improve Advanced Recycling Output

LCA and Environmental Aspects

This session will elaborate Life Cycle Assessment (LCA) in the context of advanced recycling, how such assessments should and can be performed, and discuss the open questions and challenges of how to communicate their results as well as monitoring of environmental and health aspects.

• Matthias Stratmann, nova-Institute (DE): Advanced Recycling in LCA – The Status Quo

• Edzard Scholten, BASF (DE): Environmental and Health Aspects of ChemCycling: A Measurement Program

Pyrolysis and Other Thermochemical Approaches

Pyrolysis is a versatile tool that is able to complement mechanical recycling and to produce a wide range of different products that can be utilised in the chemical and plastics industry. The boundaries to other thermochemical processes are usually fluid, but can occur under similar reaction conditions. Depending on the reactor and reaction design, different products can be obtained from the process to realise open or closed recycling loops.

• Frank Riedewald, Composite Recycling Ltd (IR): Lower OPEX and CAPEX Waste Plastic Chemical Recycling Facilities with Molten Metals

• Jasper Munier, Clariter (FR): You Don’t Need Mass Balance When You Make High-Value, High-Purity Petrochemicals From 100% Recycled Plastic Waste

• Geoff Smith, Itero Technologies (UK): Managing Waste Variability in a Pyrolysis Process

• Marcus Trygstad, Aduro Clean Technologies (CA): Advancing Chemical Recycling Through Chemical Thinking and Chemolysis

Join the event – Registration, exhibition and sponsoring

The Advanced Recycling Conference welcomes key players and stakeholders along the entire value chain of recycling materials and offers plenty of opportunity to connect and network.

ARC 2023 is accompanied by a trade exhibition that guarantees enterprises top visibility among a target audience.

The Advanced Recycling Conference is supported by industry and trade associations, non- profit organisations, research institutions and interest groups that are thematically linked to the conference: BCNP Consultants (DE), C.A.R.M.E.N. (DE), Chemical Recycling Europe (EU), CLIB (DE), IBB Netzwerk (DE), ITA - International Centre for Sustainable Textiles (DE), kunststoffland.NRW (DE), Plastics Europe (DE), Renewable Carbon Initiative (International).

To register for the event, please visit:

https://advanced-recycling.eu/registration/